Silver Bull Resources, Inc. (TSX:SVB)(NYSE MKT:SVBL) ("Silver

Bull") is pleased to provide interim results and a metallurgical

flow sheet for its metallurgical test program on the silver

mineralization at the Sierra Mojada project located in the state of

Coahuila, Northern Mexico.

Results reported in this news release pertain to test work

conducted by Kappes, Cassidy and Associates, Reno ("KCA") on the

silver mineralization from the three areas of the silver deposit:

"Shallow Silver Zone, "Centenario Zone", and "Fonteriza Zone", and

on SART test work (a metallurgical process that regenerates and

recycles the cyanide used in the leaching process of the silver)

performed by BioteQ Environmental Technologies Inc. ("BioteQ").

This news release does not include work on the "High grade" zinc

zone which is still ongoing and sits underneath and adjacent to the

silver mineralization.

HIGHLIGHTS INCLUDE:

-- An overall average silver recovery of 73.2% with peak values approx.

89.0%.

-- Recovery of between 40% - 50% of the "low grade" zinc mineralization at

the SART stage, previously thought unrecoverable (low grade zinc

resource is estimated at 1.53 billion pounds of indicated zinc metal).

-- A mining and metallurgical flow sheet that will recover silver, zinc,

and potentially lead.

-- Greater than 98% recycling of cyanide via the SART process - Cyanide is

one of the most expensive reagents used in the leaching process, so the

recycling of this will have a significant positive effect in lowering

the overall costs.

-- Room to optimize and improve recoveries to 75%-80%.

SUMMARY OF SILVER METALLURGICAL TEST WORK

Test work on leaching the silver ore at Sierra Mojada has been

conducted by KCA. Work has focused on cyanide leach recovery of the

silver, and zinc and copper, using "Bottle Roll" tests to simulate

an agitation leach system common on many mine sites.

Samples have been taken separately from drill core, mineralized

outcrop, and trenches from the "Centenario", "Fonteriza" and

"Shallow Silver" Zones of the deposit and have been crushed and

mixed to create either a "composite" sample representative of each

of the 3 zones, or a series of composite samples based on the

silver grade for each of the three zones.

To view Figure 1, please visit the following link:

http://media3.marketwire.com/docs/svb702-F1.pdf.

SUMMARY OF SILVER RESULTS

A summary of results for the cyanide leach test work on silver

recovery is shown in the table below.

----------------------------------------------------------------------------

Leach

Target Solution Calculated

KCA p80 NaCN Head,

Sample Size, Conc., gms % Ag

No. Sample Description mm g/L NaCN Ag/MT Recovery

----------------------------------------------------------------------------

64605 Centenario, Composite No. 5

(10 to 20 gms Ag/MT) 0.074 5.0 16.9 76.7%

----------------------------------------------------------------------------

64601 Centenario, Composite No. 1

(10 to 20 gms Ag/MT) 0.074 5.0 17.5 68.5%

----------------------------------------------------------------------------

64602 Centenario, Composite No. 2

(20 to 30 gms Ag/MT) 0.074 5.0 23.3 69.6%

----------------------------------------------------------------------------

64606 Centenario, Composite No. 6

(20 to 30 gms Ag/MT) 0.074 5.0 24.6 76.2%

----------------------------------------------------------------------------

65609 Centenario, Composite No.

9; (30 to 60 gms Ag/MT) 0.074 5.0 41.6 81.8%

----------------------------------------------------------------------------

65441 Centenario, Composite No.

7; (30 to 60 gms Ag/MT) 0.053 1.0 42.6 85.0%

----------------------------------------------------------------------------

64603 Centenario, Composite No.

3; (30 to 60 gms Ag/MT) 0.074 5.0 43.3 81.8%

----------------------------------------------------------------------------

65610 Centenario, Composite N0.

10: (approx. 100 gms/MT) 0.074 5.0 104.0 79.0%

----------------------------------------------------------------------------

64604 Centenario, Composite No.

4; (greater than 60 gms

Ag/MT) 0.074 5.0 105.8 88.4%

----------------------------------------------------------------------------

65608 Centenario, Composite No.

8; (greater than 60 gms

Ag/MT) 0.074 5.0 172.4 89.0%

----------------------------------------------------------------------------

65743 Fronteriza, Composite No.

1; (35 to 50 gms Ag/MT) 0.044 10.0 43.6 51.0%

----------------------------------------------------------------------------

65744 Fronteriza, Composite No.

2; 50 to 100 gms Ag/MT 0.045 5.0 67.4 55.0%

----------------------------------------------------------------------------

65745 Fronteriza, Composite No. 3

(100 to 150 gms Ag/MT) 0.040 5.0 126.2 60.0%

----------------------------------------------------------------------------

65746 Fronteriza, Composite No. 4

(150 to 200 gms Ag/MT) 0.038 10.0 182.9 62.0%

----------------------------------------------------------------------------

65747 Fronteriza, Composite No. 5

(200+ gms Ag/MT) 0.053 20.0 597.0 86.1%

----------------------------------------------------------------------------

63604 Shallow Silver Zone, Core

Composite 0.053 20.0 57.6 70.7%

----------------------------------------------------------------------------

65770 Shallow Silver, Composite

No. 2 (45 to 100 gms

Ag/MT) 0.053 20.0 65.8 68.2%

----------------------------------------------------------------------------

65771 Shallow Silver, Composite

No. 3 (100 to 150 gms

Ag/MT) 0.053 20.0 110.1 68.7%

----------------------------------------------------------------------------

AVERAGE 73.2%

Observations from these results include;

-- Silver recoveries generally show an increase with higher grade.

-- Silver recovery is grind size sensitive with finer grinds giving higher

recoveries.

-- Due to high cyanide soluable zinc values, cyanide concentration is

critical to maximize silver recovery.

Work will continue to optimize the parameters for leaching the

silver, with the average silver recovery expected to reach 75%-80%

as test parameters are optimized.

SUMMARY OF THE ZINC RESULTS

In addition to the tests assessing the silver recoveries via

cyanidation, KCA performed cyanide leach tests to determine the

recovery of the "low grade" zinc to the leach solution. The

following two tables provide the results of the zinc recoveries to

cyanide solution in the cyanide leach tests.

Zinc Recoveries

----------------------------------------------------------------------------

Target Average Head, Avg. Tails, Zn Extracted,

Sample Description NaCN, gpL Zn, mg/kg Zn, mg/kg %

----------------------------------------------------------------------------

Shallow Silver Zone 10 7,750 4,380 41%

----------------------------------------------------------------------------

Centenario 10 2,080 1,540 26%

----------------------------------------------------------------------------

Fonteriza 10 18,870 7,359 64%

----------------------------------------------------------------------------

Average All Tests 44%

----------------------------------------------------------------------------

It should be noted that the zinc recovery was still climbing at

the end of the majority of the leach tests, indicating that higher

zinc recoveries are possible if higher cyanide concentrations are

used. Silver recoveries are also expected to increase with higher

cyanide concentrations.

THE SART PROCESS:

The purpose of the "SART" process (Sulfidization, Acidification,

Recycling and Thickening) is to;

1. Regenerate and recycle the cyanide used in the leaching process of the

silver, and zinc - thereby significantly lowering cyanide costs - one of

the major costs in any leach process.

2. Recover the zinc as saleable sulphide concentrates. Selling this

concentrate will contribute significantly to reducing the net operating

costs of the SART circuit.

The studies were performed at BioteQ utilizing the leach

solution samples collected at KCA after the silver had been

precipitated out of the solution. Testing was conducted at a

laboratory bench top scale using batch testing methods to assess

the effectiveness of different process conditions. The tests were

conducted using sodium hydrosulphide (NaHS) and hydrogen sulphide

gas (H2S) as sulphide reagent sources. Test results provided values

for cyanide recovery, and zinc and copper recovery to sulfide

concentrates. The tests proved very successful and the results are

summarized in the discussion below by BioteQ.

The following were concluded after analyzing the experimental

data for various reaction conditions:

-- Recovery of WAD cyanide to free cyanide was close to 100% under

operating conditions.

-- Zinc can be recovered from the barren leach solution (BLS) using both

sulphide sources (NaHS and H2S).

-- Zinc grade of the concentrate is predicted to be between 63%-64%,

considered a high-grade zinc sulphide product.

-- The small amount of silver that was present in the BLS was removed from

solution to below detection limit of the analytical equipment and

reported to the metal sulphide solids.

MINING FLOW SHEET FOR THE SILVER MINERALIZATION AT SIERRA

MOJADA

A summary of the mining flow sheet for the silver mineralization

at Sierra Mojada is shown below. The metallurgical results reported

in this news release refer to the "VAT leach" - "Merrill Crowe" -

"SART" steps of the diagram below. The products produced at the

various steps are shown on the right hand side of the diagram.

To view Figure 2, please visit the following link:

http://media3.marketwire.com/docs/svb702-F2.pdf.

TESTWORK ON THE LEAD

Floatation testwork on the lead mineralization is currently

underway. With over 537 million pounds of contained lead metal, the

lead has the potential to provide significant upside to the

project. The ore containing the lead mineralization will already

have been milled and will only need to be passed through a

floatation cell either prior to vat leaching or after vat leaching

on the way to the tailings dam.

Tim Barry, President, CEO and director of Silver Bull states,

"We are extremely pleased with the results of the metallurgical

program. Work going forward on the metallurgy will now focus on

optimizing and improving the silver and low grade zinc recoveries

at various steps along the process, and examining the potential to

extract more value from lead and zinc. By unlocking the metallurgy

we have taken another major step forward in development of one of

the largest undeveloped silver resources in Mexico. The next step

for the company is a Preliminary Economic Assessment which we

expect to have out to the market in the third quarter of this

year."

THE NEXT STEPS GOING FORWARD

-- Cyanide leach tests will continue on the silver, low-grade zinc and

copper ore to optimize recovery and leach time. Drivers to improve

recovery will include stronger cyanide solutions, grind size of the ore,

and leaching residence times.

-- Floatation tests on the lead mineralization.

-- Floatation tests are also underway on the "high grade" zinc (greater

than 8%) mineralization which sits underneath the silver mineralization

at the eastern end of the deposit.

About Silver Bull: Silver Bull is a well funded US registered

mineral exploration company listed on both the NYSE MKT and TSX

stock exchanges and based out of Vancouver, Canada. The flag ship

"Sierra Mojada" project is located 150 kilometers north of the city

of Torreon in Coahuila, Mexico, and is highly prospective for

silver and zinc. Silver Bull also has 2 mineral licenses in Gabon,

Central Africa, which are prospective for gold, manganese, and iron

ore.

The technical information of this news release has been reviewed

and approved by William J. Pennstrom, Jr., a qualified person for

the purposes of National Instrument 43-101. Mr. Pennstrom, a

consulting process engineer and President of Pennstrom Consulting,

Inc. has acted as the Qualified Person, as defined by NI 43-101,

for evaluation of the metallurgical testing data. He has over 30

years of experience in mineral process design and operation, and

has been an independent process and metallurgical consultant for

the mining industry for the last 12 years. He is a Registered

Member of the Society of Mining, Metallurgy and Exploration (SME

Member No. 2503900). Mr. Pennstrom and Pennstrom Consulting Inc.

are both independent of the Company under NI 43-101.

On behalf of the Board of Directors

Tim Barry, MAusIMM, Chief Executive Officer, President and

Director

Cautionary Note to U.S. Investors concerning estimates of

Indicated and Inferred Resources: This press release uses the terms

"indicated resources" and "inferred resources" which are defined

in, and required to be disclosed by, NI 43-101. We advise U.S.

investors that these terms are not recognized by the United States

Securities and Exchange Commission (the "SEC"). The estimation of

indicated resources involves greater uncertainty as to their

existence and economic feasibility than the estimation of proven

and probable reserves. U.S. investors are cautioned not to assume

that indicated mineral resources will be converted into reserves.

The estimation of inferred resources involves far greater

uncertainty as to their existence and economic viability than the

estimation of other categories of resources. U.S. investors are

cautioned not to assume that estimates of inferred mineral

resources exist, are economically minable, or will be upgraded into

measured or indicated mineral resources. Under Canadian securities

laws, estimates of inferred mineral resources may not form the

basis of feasibility or other economic studies.

Disclosure of "contained ounces" in a resource is permitted

disclosure under Canadian regulations, however the SEC normally

only permits issuers to report mineralization that does not

constitute "reserves" by SEC standards as in place tonnage and

grade without reference to unit measures. Accordingly, the

information contained in this press release may not be comparable

to similar information made public by U.S. companies that are not

subject NI 43-101.

Cautionary note regarding forward-looking statements: This news

release contains forward-looking statements regarding future events

and Silver Bull's future results that are subject to the safe

harbors created under the U.S. Private Securities Litigation Reform

Act of 1995, the Securities Act of 1933, as amended (the

"Securities Act"), and the Securities Exchange Act of 1934, as

amended (the "Exchange Act"), and applicable Canadian securities

laws. Forward-looking statements include, among others, statements

regarding forecasted of indicated and inferred resources,

metallurgical optimization results, ability to use the SART process

to recycle cyanide and recover zinc and copper, and the timing of

the preparation and completion of a Preliminary Economic Analysis.

These statements are based on current expectations, estimates,

forecasts, and projections about Silver Bull's exploration

projects, the industry in which Silver Bull operates and the

beliefs and assumptions of Silver Bull's management. Words such as

"expects", "anticipates", "targets", "goals", "projects",

"intends", "plans", "believes", "seeks", "estimates", "continues",

"may", variations of such words, and similar expressions and

references to future periods, are intended to identify such

forward-looking statements. Forward-looking statements are subject

to a number of assumptions, risks and uncertainties, many of which

are beyond our control, including such factors as the results of

exploration activities and whether the results continue to support

continued exploration activities, unexpected variations in ore

grade, types and metallurgy, volatility and level of commodity

prices, the availability of sufficient future financing, and other

matters discussed under the caption "Risk Factors" in our Annual

Report on Form 10-K for the fiscal year ended October 31, 2012, as

amended, and our other periodic and current reports filed with the

SEC and available on www.sec.gov and with the Canadian securities

commissions available on www.sedar.com. Readers are cautioned that

forward-looking statements are not guarantees of future performance

and that actual results or developments may differ materially from

those expressed or implied in the forward-looking statements. Any

forward-looking statement made by us in this release is based only

on information currently available to us and speaks only as of the

date on which it is made. We undertake no obligation to publicly

update any forward-looking statement, whether written or oral, that

may be made from time to time, whether as a result of new

information, future developments or otherwise.

Contacts: Silver Bull Resources, Inc. Matt Hallaran Investor

Relations +1 604 336 8096info@silverbullresources.com

www.silverbullresources.com

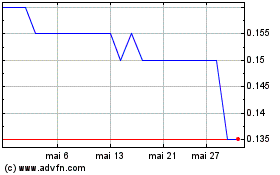

Silver Bull Resources (TSX:SVB)

Gráfico Histórico do Ativo

De Fev 2025 até Mar 2025

Silver Bull Resources (TSX:SVB)

Gráfico Histórico do Ativo

De Mar 2024 até Mar 2025