Eloro Resources Ltd. (TSX: ELO; OTCQX: ELRRF; FSE:

P2QM) (“Eloro”, or the “Company”) is pleased to announce

major advances on metallurgy for the Iska Iska silver-tin

polymetallic project in the Potosi Department of southern Bolivia.

These tests were directed by Mike Hallewell, C.Eng., Eloro’s Senior

Strategic Metallurgist and a qualified person (QP) as defined by

National Instrument 43-101 (NI 43-101). in consultation with Micon

International Limited Principal Metallurgist, Richard Gowans,

P.Eng., an independent QP.

Work by the Eloro geological team at Iska Iska

led by Dr. Bill Pearson, P.Geo., Executive Vice President of

Exploration and Dr. Osvaldo Arce, P.Geo., Manager of Minera Tupiza,

indicates that Santa Barbara is essentially two major deposits in

one as shown in Figure 1. Tin (Sn) mineralization with silver (Ag)

dominates in the western and deeper portions of the deposit (Tin

Domain) while in the eastern and southern shallower parts of the

deposit, polymetallic silver-zinc-lead (Ag-Zn-Pb) mineralization

predominates (Polymetallic Domain). The overall deposit as

presently drilled extends more than 1,200m along strike, is up to

800m wide and extends to a depth of at least 1,000m with

mineralization open in all directions.

Tom Larsen, CEO of Eloro, said: “These positive

metallurgical tests, particularly the “Ore-sorting” tests at TOMRA,

have a major positive impact on the potential future production at

Iska Iska. For this reason, and in consultation with our

independent consultants, Micon International, we deferred

completion of the inaugural MRE until these tests were completed

and the results could be fully incorporated into the final MRE

which is now expected to be released in latter August.”

Mike Hallewell, C.Eng, Eloro’s Senior Strategic

Metallurgist commented: “The level of metallurgical and

pyrometallurgical work that has been conducted thus far at Iska

Iska is exceptionally high for an inaugural MRE but is justifiable

due to the significance of this large potentially open pittable tin

and polymetallic resource. This additional

metallurgical/mineralogical knowledge will enable Eloro to rapidly

move towards a preliminary economic assessment (PEA).”

“Ore-Sorting” Tests

Metallurgically the two different domains

require different approaches to optimize recoveries. As much of the

mineralization in both domains occurs in veins and vein breccias,

it was felt that “ore-sorting” technology developed by TOMRA could

have a significant impact by selectively removing waste material

resulting in a significant reduction in operating costs while at

the same time producing a major increase in grades of feed to the

grinding circuit.

256 rocks representing five different

lithological groups within the Polymetallic Domain and five

different lithological and tin grade groups within the Tin Domain

were scanned using the on-site GeologicAI core scanner and then

subsequently sent for amenability testing at TOMRA in Wedel,

Germany. The preliminary images and assays indicate a positive

response to XRT Ore sorting.

Based upon these results, the preliminary

indications are at least 40% of the run-of-mine (ROM) polymetallic

mineralization could be rejected as waste while for the Tin Domain,

as much as 80% of the weight can be rejected as sub – cutoff grade

(COG) waste. Ore sorting will significantly increase concentrator

feed grades which will enhance concentrator recovery in both

domains. In addition, bulk mining techniques can be employed

without resultant dilution issues and this will reduce downstream

processing costs.

The positive results obtained justify the

diamond drilling of larger size diameter holes to produce bulk

samples of both Polymetallic and Tin Domains for “Cascade” testing

at TOMRA, Germany. The resultant XRT pre-concentrated product will

be used for the downstream PEA studies.

Optimizing Tin Recovery

Wardell Armstrong International, based at the

old Wheal Jane tin mine site in Cornwall, England have conducted

further tin optimisation testing on a composite sample from the tin

domain, drawing on their strong historical background with tin

studies. The main thrust of this work was to identify ways of

increasing the tin recovery in the concentrator and consisted of

Falcon Continuous Roughing followed by multi-gravity separators

(MGS) and cleaning of Falcon Rougher Concentrates. These

multi-gravity technologies can recover the bulk of the recovered

tin in as coarse a grain size possible. The Falcon tailings are

then reground prior to a tin flotation rougher stage where much

finer cassiterite is recovered using MGS cleaning of the resultant

tin flotation rougher concentrates. The combined multi gravity

concentrator and tin float concentrator tin recovery was increased

to 50% using this flowsheet and further optimisation studies of

this flowsheet have been identified which will form part of the PEA

study using the XRT pre-concentrated products as mentioned

above.

The University of Oruro has also tested other

pre-concentration techniques including Dense Media Separation

(“DMS”) using heavy liquids. The DMS testwork results for the three

different grade samples tested were positive, matching the XRT “Ore

sorting” mentioned above where as much as80% of the weight can be

rejected as floats at sub-COG waste in the Tin Domain. This is a

positive result and provides further options to increase the

quantity of waste rejected by using DMS as a potential further

stage of pre-concentration on XRT products and/or the nominal -10mm

that is too fine to be XRT “Ore Sorted”. This provides further

confidence that the low-grade tin domain can be effectively

upgraded.

Figure 1 – Plan Map Showing Major Tin and

Polymetallic Domains in the Santa Barbara Deposit, Iska

Iska

Qualified Person

Dr. Osvaldo Arce, P. Geo., General Manager of

Eloro’s Bolivian subsidiary, Minera Tupiza S.R.L., and a Qualified

Person (QP) in the context of NI 43-101, has reviewed and approved

the technical content of this news release. Dr. Bill Pearson,

P.Geo., Executive Vice President Exploration Eloro, and who has

more than 45 years of worldwide mining exploration experience,

including extensive work in South America, manages the overall

technical program, working closely with Dr. Osvaldo Arce, P.Geo.

Dr. Quinton Hennigh, P.Geo., Senior Technical Advisor to Eloro and

Independent Technical Advisor, Mr. Charley Murahwi P. Geo., FAusIMM

of Micon are regularly consulted on technical aspects of the

project.

Metallurgical work was directed by Mike

Hallewell, B.Sc, F.S.A.I.M.M., F.I.M.M.M., C.Eng., Eloro’s Senior

Strategic Metallurgist, a QP as defined by NI 43-101, in

consultation with Micon International’s Principal Metallurgist,

Richard Gowans, P.Eng., an independent QP as defined by NI 43-101.

“Ore-sorting” tests were completed at TOMRA’s facilities in Wedel,

Germany. TOMRA GmbH are a leading technical authority in XRT Ore

sorting. Note that the term “Ore” is part of the registered product

name of TOMRA and the use of the term “ore” in this press release

does not imply that the mineralization at Iska Iska is “ore” as

defined by NI 43-101.

Tin optimization tests were completed at the

facilities of Wardell Armstrong International in Cornwall, England.

Wardell Armstrong International are an internationally recognised

consulting group. The metallurgical testwork carried out at the

University of Oruro, Bolivia facility has been found to yield

accurate results in comparison to similar analysis at

internationally accredited laboratories hence the results are

considered reliable for preliminary analysis.

Eloro utilized both ALS and AHK for drill core

analysis, both of whom are major international accredited

laboratories. Drill samples sent to ALS are prepared in both

ALS Bolivia Ltda’s preparation facility in Oruro, Bolivia and

the preparation facility operated by AHK in Tupiza with pulps sent

to the main ALS Global laboratory in Lima for analysis. More

recently Eloro has had ALS send pulps to their laboratory at Galway

in Ireland. Eloro employs an industry standard QA/QC program with

standards, blanks and duplicates inserted into each batch of

samples analyzed with selected check samples sent to a separate

accredited laboratory.

Drill core samples sent to AHK Laboratories are

prepared in a preparation facility installed and managed by AHK in

Tupiza with pulps sent to the AHK laboratory in Lima, Peru. Au and

Sn analysis on these samples is done by ALS Bolivia Ltda in Lima.

Check samples between ALS and AHK are regularly done as a QA/QC

check. AHK is following the same analytical protocols used as with

ALS and with the same QA/QC protocols.

About Iska Iska

Iska Iska silver-tin polymetallic project is a

road accessible, royalty-free property, wholly controlled by the

Title Holder, Empresa Minera Villegas S.R.L. and is located 48 km

north of Tupiza city, in the Sud Chichas Province of the Department

of Potosi in southern Bolivia. Eloro has an option to earn a 100%

interest in Iska Iska.

Iska Iska is a major silver-tin polymetallic

porphyry-epithermal complex associated with a Miocene possibly

collapsed/resurgent caldera, emplaced on Ordovician age rocks with

major breccia pipes, dacitic domes and hydrothermal breccias. The

caldera is 1.6km by 1.8km in dimension with a vertical extent of at

least 1km. Mineralization age is similar to Cerro Rico de Potosí

and other major deposits such as San Vicente, Chorolque, Tasna and

Tatasi located in the same geological trend.

Eloro began underground diamond drilling from

the Huayra Kasa underground workings at Iska Iska on September 13,

2020. On November 18, 2020, Eloro announced the discovery of a

significant breccia pipe with extensive silver polymetallic

mineralization just east of the Huayra Kasa underground workings

and a high-grade gold-bismuth zone in the underground workings. On

November 24, 2020, Eloro announced the discovery of the SBBP

approximately 150m southwest of the Huayra Kasa underground

workings.

Subsequently, on January 26, 2021, Eloro

announced significant results from the first drilling at the SBBP

including the discovery hole DHK-15 which returned 129.60 g Ag eq/t

over 257.5m (29.53g Ag/t, 0.078g Au/t, 1.45%Zn, 0.59%Pb, 0.080%Cu,

0.056%Sn, 0.0022%In and 0.0064% Bi from 0.0m to 257.5m. Subsequent

drilling has confirmed significant values of Ag-Sn polymetallic

mineralization in the SBBP and the adjacent CBP. A substantive

mineralized envelope which is open along strike and down-dip

extends around both major breccia pipes. Continuous channel

sampling of the Santa Barbara Adit located to the east of SBBP

returned 442 g Ag eq/t (164.96 g Ag/t, 0.46%Sn, 3.46% Pb and 0.14%

Cu) over 166m including 1,092 g Ag eq/t (446 g Ag/t, 9.03% Pb and

1.16% Sn) over 56.19m. The west end of the adit intersects the end

of the SBBP.

Since the initial discovery hole, Eloro has

released a number of significant drill results in the SBBP and the

surrounding mineralized envelope which along with geophysical data

has defined an extensive target zone. In its September 20, 2022

press release, the Company reported that new downhole geophysical

data has significantly extended the strike length of the high-grade

feeder zone at Santa Barbara a further 250m along strike to the

south-southeast from existing drilling. The 3D inverse magnetic

model which correlates very strongly with the conductive zone

suggested that the high-grade feeder zone may extend across the

entire caldera for as much as a further 1 km along strike for a

total potential strike length of at least 2 km. As reported, the

definition drill program was modified to sectionally drill this

potential extension with the intention of defining a major open

pittable deposit in the valley of the caldera.

The Company completed 84,495m of drilling in 122

holes from the definition drill program in the Santa Barbara target

area.

On November 22, 2022, Eloro announced the

acquisition of the Mina Casiterita and Mina Hoyada properties

covering 14.75 km2 southwest and west of Iska Iska. These

properties connect with the TUP-3 and TUP-6 claims previously

staked by Eloro. Eloro has also staked additional land in the area.

Following the acquisition, the total land package in the Iska Iska

area to be controlled by Eloro will total 1,935 quadrants covering

483.75 km2.

Artisanal mining in the 1960’s identified high

grade tin (Sn) veins on the Mina Casiterita property that are

hosted in an intrusive dacite. Production from 1962 to 1964 is

reported by the Departamento Nacional de Geología in Bolivia to be

69.85 tonnes grading 50.60% Sn.

Recently completed magnetic surveys by Eloro has

outlined an extensive, near surface, magnetic intrusive body on the

Mina Casiterita property immediately southwest of Iska Iska. This

intrusive hosts the previously mined high-grade tin veins and is

very likely the continuation of the porphyry tin intrusion

projected to be below the epithermal Ag-Sn-Zn-Pb mineralization at

Iska Iska.

Work by the Eloro geological team at Iska Iska

indicates that Santa Barbara is essentially two major deposits in

one. Tin (Sn) mineralization with silver (Ag) dominates in the

western and deeper portions of the deposit (Tin Domain) while in

the eastern and southern shallower parts of the deposit,

polymetallic silver-zinc-lead (Ag-Zn-Pb) mineralization

predominates (Polymetallic Domain). The overall deposit as

presently drilled extends more than 1,200m along strike, is up to

800m wide and extends to a depth of at least 1,000m with

mineralization open in all directions.

About Eloro Resources Ltd.

Eloro is an exploration and mine development

company with a portfolio of gold and base-metal properties in

Bolivia, Peru and Quebec. Eloro has an option to acquire a 100%

interest in the highly prospective Iska Iska Property, which can be

classified as a polymetallic epithermal-porphyry complex, a

significant mineral deposit type in the Potosi Department, in

southern Bolivia. A recent NI 43-101 Technical Report on Iska Iska,

which was completed by Micon International Limited, is available on

Eloro’s website and under its filings on SEDAR. Iska Iska is a

road-accessible, royalty-free property. Eloro also owns an 82%

interest in the La Victoria Gold/Silver Project, located in the

North-Central Mineral Belt of Peru some 50 km south of Barrick’s

Lagunas Norte Gold Mine and Pan American Silver’s La Arena Gold

Mine.

For further information please contact

either Thomas G. Larsen, Chairman and CEO or Jorge Estepa,

Vice-President at (416) 868-9168.

Information in this news release may contain

forward-looking information. Statements containing forward-looking

information express, as at the date of this news release, the

Company’s plans, estimates, forecasts, projections, expectations,

or beliefs as to future events or results and are believed to be

reasonable based on information currently available to the Company.

There can be no assurance that forward-looking statements will

prove to be accurate. Actual results and future events could differ

materially from those anticipated in such statements. Readers

should not place undue reliance on forward-looking information.

Neither the TSX nor its Regulation Services

Provider (as that term is defined in the policies of the TSX)

accepts responsibility for the adequacy or accuracy of this

release.

A photo accompanying this announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/42ba87ae-c709-4ffe-9ef2-971c74dab8df

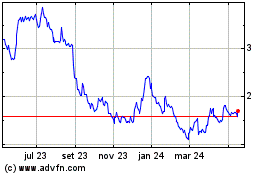

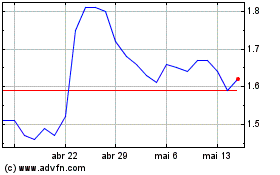

Eloro Resources (TSX:ELO)

Gráfico Histórico do Ativo

De Out 2024 até Nov 2024

Eloro Resources (TSX:ELO)

Gráfico Histórico do Ativo

De Nov 2023 até Nov 2024