RICHMOND, Va., Feb. 12 /PRNewswire-FirstCall/ -- Tredegar

Corporation (NYSE:TG) reported fourth-quarter net income from

continuing operations of $10.0 million (29 cents per share)

compared to $5.9 million (17 cents per share) in the fourth quarter

of 2008. Earnings from continuing manufacturing operations in the

fourth quarter were $5.2 million (15 cents per share) versus $10.2

million (30 cents per share) last year. Fourth-quarter sales from

continuing operations decreased to $161.8 million from $192.7

million in 2008. A summary of results for continuing operations for

the three and twelve months ended December 31, 2009 and 2008 is

shown below: (In Millions, Except Per-Share Data) Three Months

Ended Year Ended December 31 December 31 ----------- -----------

2009 2008 2009 2008 ---- ---- ---- ---- Sales $161.8 $192.7 $648.6

$883.9 Income (loss) from continuing operations as reported under

generally accepted accounting principles (GAAP) $10.0 $5.9 $(1.4)

$29.6 After-tax effects of: Goodwill impairment relating to

aluminum extrusions business - - 30.6 - Losses associated with

plant shutdowns, asset impairments and restructurings 1.5 5.1 2.4

8.9 Net gains from sale of assets and other items (6.3) (.8) (2.7)

(6.6) ---- --- ---- ---- Income from continuing manufacturing

operations* $5.2 $10.2 $28.9 $31.9 --- ----- ----- ----- Diluted

earnings (loss) per share from continuing operations as reported

under GAAP $.29 $.17 $(.04) $.87 After-tax effects per diluted

share of: Goodwill impairment relating to aluminum extrusions

business - - .90 - Losses associated with plant shutdowns, asset

impairments and restructurings .04 .15 .07 .26 Net gains from sale

of assets and other items (.18) (.02) (.08) (.20) ---- ---- ----

---- Diluted earnings per share from continuing manufacturing

operations* $.15 $.30 $.85 $.93 --- --- --- --- * The after-tax

effects of unusual items, goodwill impairments, losses associated

with plant shutdowns, asset impairments and restructurings, and

gains or losses from sale of assets and other items have been

presented separately and removed from net income and earnings per

share from continuing operations as reported under GAAP to

determine Tredegar's presentation of income and earnings per share

from continuing manufacturing operations. Income and earnings per

share from continuing manufacturing operations are key financial

and analytical measures used by management to gauge the operating

performance of its continuing manufacturing businesses. They are

not intended to represent the stand- alone results for Tredegar's

continuing manufacturing businesses under GAAP and should not be

considered as an alternative to net income or earnings per share as

defined by GAAP. They exclude items that we believe do not relate

to Tredegar's ongoing manufacturing operations. Further detail

regarding the items excluded from income from continuing

manufacturing operations is provided in the notes to the financial

tables included in this press release. Nancy M. Taylor, Tredegar's

newly-elected president and chief executive officer, said "The

financial performance of our films business in 2009 was strong.

Operating profit increased 19% on lower volume as our film division

responded well to the economic uncertainties of the past year by

successfully executing on aggressive productivity, cost reduction

and asset management initiatives. As we move forward with

longer-term growth efforts in 2010, we expect some increased

spending. Our challenge will be to mitigate the impact of the

higher spending and other cost pressures through a continued focus

on productivity gains and cost reductions. "The economic

environment for our aluminum business worsened in 2009 as

operations were affected by steep declines in the nonresidential

construction market. The rigorous efforts of our employees to lower

costs, effectively manage working capital and improve customer

service have helped us during this difficult time and will provide

significant operating leverage as volume returns. Given the

uncertainty as to the timing of a meaningful recovery in the

nonresidential construction market, the division is committed to

continue to reduce its breakeven point while strategically

investing in the business to ensure sustained improvement in

product and service offerings to our customers." Ms. Taylor

continued: "We believe growth initiatives in our existing

businesses and our continued focus on cost reductions, along with

the effective use of our strong balance sheet, positions us well to

benefit from eventual improvements in economic conditions in the

markets that we serve." MANUFACTURING OPERATIONS Film Products

Fourth-quarter net sales (sales less freight) in Film Products were

$119.0 million, down 3.9% from $123.8 million in the fourth quarter

of 2008, while operating profit from ongoing operations decreased

to $15.4 million in the fourth quarter of 2009 from $19.2 million

in 2008. Volume was 52.6 million pounds in the fourth quarter of

2009, an increase of 4.4% from 50.3 million pounds in the fourth

quarter of 2008. Net sales, operating profit and volume in the

third quarter of 2009 were $123.4 million, $21.8 million, and 55.2

million pounds, respectively. Net sales declined in the fourth

quarter of 2009 compared with the fourth quarter of 2008 primarily

due to the impact on selling prices from the pass-through of lower

average resin costs, partially offset by sales volume increases,

mostly of higher-value surface protection and personal care

materials, and the favorable effect of changes in the U.S. dollar

value of currencies for operations outside of the U.S. Operating

profit from ongoing operations was lower in the fourth quarter of

2009 versus the same period in 2008 primarily due to the favorable

effect from the lag in the pass through of substantially lower

resin cost recognized in the fourth quarter of 2008. Film Products

also experienced increasing cost pressures in the fourth quarter of

2009, which were partially offset by higher sales volume in the

quarter. Net sales in Film Products for 2009 were $455.0 million, a

decrease of 13.0% from $522.8 million for 2008. Operating profit

from ongoing operations was $64.4 million in 2009, up 19.4% from

$53.9 million in the prior year. Volume was 206.7 million pounds in

2009, down 6.6% from 221.2 million pounds in 2008. Net sales in

2009 declined primarily due to the impact on selling prices from

the pass-through of lower average resin costs, volume declines in

personal care materials and packaging films and the unfavorable

effect of changes in the U.S. dollar value of currencies for

operations outside the U.S. during the year. Operating profit from

ongoing operations increased in 2009 versus 2008 as cost reduction

efforts, productivity gains, the positive impact of the change in

product mix driven mostly by an increase in sales of higher-value

surface protection materials and the lag in the pass-through of

reduced resin costs were partially offset by the lower overall

sales volumes and the unfavorable effect of the currency changes

noted above. The company estimates that the approximate impact on

fourth-quarter operating profit from the lag in the pass-through of

changes in average resin costs and adjustments for inventories

accounted for under the last-in first-out method (LIFO) was not

significant in 2009 and was a positive $6.6 million in 2008. The

estimated full-year impact of the resin pass-through lag and LIFO

adjustments was a positive $1.7 million in 2009 and a negative

$600,000 in 2008. The company estimates that changes in the U.S.

dollar value of currencies for operations outside of the U.S. had a

favorable impact on operating profit of $400,000 in the fourth

quarter of 2009 compared to the fourth quarter of 2008, and an

unfavorable impact of approximately $1.9 million in 2009 compared

with 2008. Capital expenditures in Film Products were $11.5 million

in 2009 compared with $11.1 million in 2008, and are projected to

be approximately $24 million in 2010 as spending returns to more

normalized levels. Depreciation expense was $32.2 million in 2009

compared with $34.5 million in the prior year, and is projected to

be approximately $36 million in 2010. Aluminum Extrusions

Fourth-quarter net sales from continuing operations in Aluminum

Extrusions were $38.5 million, down 40.3% from $64.5 million in the

fourth quarter of 2008. Operating losses from ongoing U.S.

operations were $4.4 million in the fourth quarter of 2009, a

negative change of $6.7 million from operating profits of $2.3

million in the fourth quarter of 2008. Volume from continuing

operations was 19.1 million pounds in the fourth quarter of 2009,

down 32.7% from 28.4 million pounds in the fourth quarter of 2008.

Net sales in Aluminum Extrusions for 2009 declined 47.8% to $177.5

million from $340.3 million in 2008. Operating losses from ongoing

U.S. operations were $6.5 million in 2009, a $16.6 million negative

change from operating profits of $10.1 million in 2008. Volume was

91.5 million pounds in 2009, down 32.8% from 136.2 million pounds

in the prior year. The net sales declines in the fourth quarter and

full year of 2009 compared with the corresponding period in 2008

were mainly due to lower sales volume. In addition, the full-year

comparison was affected by lower average selling prices driven by a

decrease in average aluminum costs. Weak market conditions led to

decreased shipments in most markets. Operating losses from ongoing

U.S. operations reported in the fourth quarter and all of 2009 were

primarily driven by lower sales volumes. Operating results for the

fourth quarter 2009 versus 2008 were also negatively impacted by

higher adjustments for inventories valued under LIFO in 2008 and

adjustments made to a provision for doubtful accounts in 2009

primarily related to the bankruptcy of a large customer. Capital

expenditures for continuing operations in Aluminum Extrusions were

$22.5 million in 2009 compared with $9.7 million in the prior year.

Current year capital expenditures include $19.0 million related to

the 18-month project to expand capacity at our plant in Carthage,

Tennessee. Production on the new aluminum extrusion press started

in late December 2009, and the new capacity will be dedicated to

serving customers in the nonresidential construction sector.

Capital expenditures are projected to be approximately $6.4 million

in 2010. Depreciation expense was $7.6 million in 2009 compared

with $8.0 million in 2008, and is projected to be approximately

$9.5 million in 2010. OTHER ITEMS Net pension income from

continuing operations was $544,000 in the fourth quarter and $3.1

million in 2009, an unfavorable change of $655,000 (1 cent per

share after taxes) and an unfavorable change of $1.8 million (3

cents per share after taxes), respectively, from amounts recognized

in the comparable periods of 2008. Most of the change in pension

income is reflected in "Corporate expenses, net" in the operating

profit by segment table. The Company contributed approximately

$129,000 to its pension plans for continuing operations in 2009 and

expects to contribute a similar amount in 2010. Corporate expenses,

net increased in 2009 versus 2008 primarily due to adjustments made

to accruals for certain performance-based compensation programs and

the unfavorable change in pension income noted above. Interest

expense, which includes the amortization of debt issue costs, was

$198,000 in the fourth quarter of 2009, compared to $472,000 in the

fourth quarter of 2008, and $783,000 and $2.4 million in 2009 and

2008, respectively, primarily due to reductions in average debt

levels and lower average interest rates in 2009. The effective tax

rate used to compute income taxes from continuing manufacturing

operations was 24.0% in the fourth quarter of 2009 compared with

41.2% in the fourth quarter of 2008, and 33.2% in 2009 compared

with 39.9% in 2008. The decrease in the effective tax rate for

continuing manufacturing operations for 2009 versus 2008, which had

a favorable impact of approximately 3 cents per share during the

fourth quarter and a favorable impact of approximately 9 cents per

share in the full year, was primarily due to the recognition of a

net tax benefit related to the reversal of income tax contingency

accruals upon the favorable conclusion of IRS and state tax

examinations through 2003 recognized during 2009, lower effective

rates for operations outside the U.S., lower state income taxes and

higher research and development tax credits. Overall results for

continuing operations for the quarter and annual periods include

special items. After-tax charges for continuing operations for

plant shutdowns, asset impairments and restructurings and gains and

losses from the sale of assets and other items were an after-tax

net gain of 14 cents and an after-tax net loss of 13 cents per

share in the fourth quarters of 2009 and 2008, respectively, and an

after-tax net gain of 1 cent in 2009 and an after-tax net loss of 6

cents per share in 2008. In addition, a non-cash goodwill

impairment charge of $30.6 million (after-tax), or 90 cents per

share, was recorded for Aluminum Extrusions in the first quarter of

2009. Further details regarding these items are provided in the

financial tables included with this press release. Tredegar's

investment in Harbinger Capital Partners Special Situations Fund,

L.P. had a reported capital account value of $14.5 million at

December 31, 2009, compared with $10.1 million at December 31,

2008. This investment has a carrying value in Tredegar's balance

sheet of $10.0 million, which represents the amount invested on

April 2, 2007. CAPITAL STRUCTURE AND ADJUSTED EBITDA Net cash (cash

and cash equivalents in excess of debt) was $89.5 million at

December 31, 2009, compared with net cash of $23.3 million at

December 31, 2008. Adjusted EBITDA from continuing manufacturing

operations, a key valuation and borrowing capacity measure, was

$84.0 million for the year ended December 31, 2009, down from $98.0

million for the year ended December 31, 2008. See notes to

financial statements and tables for reconciliations to comparable

GAAP measures. FORWARD-LOOKING AND CAUTIONARY STATEMENTS Some of

the information contained in this press release may constitute

"forward-looking statements" within the meaning of the "safe

harbor" provisions of the Private Securities Litigation Reform Act

of 1995. When we use the words "believe," "estimate," "anticipate,"

"expect," "project," "likely," "may" and similar expressions, we do

so to identify forward-looking statements. Such statements are

based on our then current expectations and are subject to a number

of risks and uncertainties that could cause actual results to

differ materially from those addressed in the forward-looking

statements. It is possible that our actual results and financial

condition may differ, possibly materially, from the anticipated

results and financial condition indicated in these forward-looking

statements. Factors that could cause actual results to differ from

expectations include, without limitation: Film Products is highly

dependent on sales to one customer -- The Procter & Gamble

Company; growth of Film Products depends on its ability to develop

and deliver new products at competitive prices; sales volume and

profitability of continuing operations in Aluminum Extrusions are

cyclical and highly dependent on economic conditions of end-use

markets in the U.S., particularly in the construction, distribution

and transportation industries, and are also subject to seasonal

slowdowns; our substantial international operations subject us to

risks of doing business in foreign countries, which could adversely

affect our business, financial condition and results of operations;

our future performance is influenced by costs incurred by our

operating companies including, for example, the cost of energy and

raw materials; and the factors discussed in the reports Tredegar

files with or furnishes to the Securities and Exchange Commission

(the "SEC") from time-to-time, including the risks and important

factors set forth in additional detail in "Risk Factors" in Part I,

Item 1A of Tredegar's 2008 Annual Report on Form 10-K filed with

the SEC. Readers are urged to review and consider carefully the

disclosures Tredegar makes in its filings with the SEC. Tredegar

does not undertake to update any forward-looking statement made in

this press release to reflect any change in management's

expectations or any change in conditions, assumptions or

circumstances on which such statements are based. To the extent

that the financial information portion of this release contains

non-GAAP financial measures, it also presents both the most

directly comparable financial measures calculated and presented in

accordance with GAAP and a quantitative reconciliation of the

difference between any such non-GAAP measures and such comparable

GAAP financial measures. Accompanying the reconciliation is

management's statement concerning the reasons why management

believes that presentation of non-GAAP measures provides useful

information to investors concerning Tredegar's financial condition

and results of operations. Based in Richmond, Va., Tredegar

Corporation is a global manufacturer of plastic films and aluminum

extrusions. Tredegar Corporation Condensed Consolidated Statements

of Income (In Thousands, Except Per-Share Data) (Unaudited) Fourth

Quarter Ended Year Ended December 31 December 31 -----------

----------- 2009 2008 2009 2008 ---- ---- ---- ---- Sales $161,770

$192,702 $648,613 $883,899 Other income (expense), net (a) (d) (e)

6,807 1,412 8,464 10,341 ----- ----- ----- ------ 168,577 194,114

657,077 894,240 ------- ------- ------- ------- Cost of goods sold

(a) 130,281 153,795 516,933 739,721 Freight 4,294 4,434 16,085

20,782 Selling, R&D and general expenses 19,166 16,967 72,337

69,704 Amortization of intangibles 30 30 120 123 Interest expense

198 472 783 2,393 Asset impairments and costs associated with exit

and disposal activities (a) 1,468 7,231 2,950 12,390 Goodwill

impairment charge (b) - - 30,559 - --- --- ------ --- 155,437

182,929 639,767 845,113 ------- ------- ------- ------- Income from

continuing operations before income taxes 13,140 11,185 17,310

49,127 Income taxes (e) 3,159 5,272 18,663 19,486 ----- -----

------ ------ Income (loss) from continuing operations 9,981 5,913

(1,353) 29,641 Loss from discontinued operations (f) - 225 - (705)

--- --- --- ---- Net income (loss) (c) $9,981 $6,138 $(1,353)

$28,936 ------ ------ ------- ------- Earnings (loss) per share:

Basic: Continuing operations $.30 $.17 $(.04) $.87 Discontinued

operations - .01 - (.02) --- --- --- ---- Net income (loss) $.30

$.18 $(.04) $.85 ---- ---- ----- ---- Diluted: Continuing

operations $.29 $.17 $(.04) $.87 Discontinued operations - .01 -

(.02) --- --- --- ---- Net income (loss) $.29 $.18 $(.04) $.85 ----

---- ----- ---- Shares used to compute earnings (loss) per share:

Basic 33,825 33,782 33,861 33,977 Diluted 33,871 33,990 33,861

34,194 Tredegar Corporation Net Sales and Operating Profit by

Segment (In Thousands) (Unaudited) Fourth Quarter Ended Year Ended

December 31 December 31 ----------- ----------- 2009 2008 2009 2008

--- --- --- --- Net Sales Film Products $119,023 $123,809 $455,007

$522,839 Aluminum Extrusions 38,453 64,459 177,521 340,278 ------

------ ------- ------- Total net sales 157,476 188,268 632,528

863,117 Add back freight 4,294 4,434 16,085 20,782 ----- -----

------ ------ Sales as shown in the Consolidated Statements of

Income $161,770 $192,702 $648,613 $883,899 -------- --------

-------- -------- Operating Profit (Loss) Film Products: Ongoing

operations $15,401 $19,195 $64,379 $53,914 Plant shutdowns, asset

impairments, restructurings and other (a) (1,186) (6,648) (1,846)

(11,297) Aluminum Extrusions (f): Ongoing operations (4,404) 2,323

(6,494) 10,132 Goodwill impairment charge (b) - - (30,559) - Plant

shutdowns, asset impairments, restructurings and other (a) 778 (72)

(639) (687) AFBS: Gain on sale of investments in Theken Spine and

Therics, LLC (d) 1,818 - 1,968 1,499 ----- ----- ----- ----- Total

12,407 14,798 26,809 53,561 Interest income 157 351 806 1,006

Interest expense 198 472 783 2,393 Gain on the sale of corporate

assets (e) - - 404 1,001 Gain from write-up of an investment

accounted for under the fair value method (e) 5,100 600 5,100 5,600

Stock option-based compensation costs 465 266 1,692 782 Corporate

expenses, net (a) 3,861 3,826 13,334 8,866 ----- ----- ------ -----

Income from continuing operations before income taxes 13,140 11,185

17,310 49,127 Income taxes (e) 3,159 5,272 18,663 19,486 -----

----- ------ ------ Income (loss) from continuing operations 9,981

5,913 (1,353) 29,641 Loss from discontinued operations (f) - 225 -

(705) --- --- --- ---- Net income (loss) (c) $9,981 $6,138 $(1,353)

$28,936 ------ ------ ------- ------- Tredegar Corporation

Condensed Consolidated Balance Sheets (In Thousands) (Unaudited)

December 31, December 31, 2009 2008 --- --- Assets Cash & cash

equivalents $90,663 $45,975 Accounts & notes receivable, net

74,014 91,400 Income taxes recoverable 4,016 12,549 Inventories

35,522 36,809 Deferred income taxes 5,750 7,654 Prepaid expenses

& other 5,335 5,374 ----- ----- Total current assets 215,300

199,761 Property, plant & equipment, net 230,876 236,870 Other

assets 45,561 38,926 Goodwill & other intangibles (b) 104,542

135,075 ------- ------- Total assets $596,279 $610,632 --------

-------- Liabilities and Shareholders' Equity Accounts payable

$53,770 $54,990 Accrued expenses 34,930 38,349 Current portion of

long-term debt 451 529 --- --- Total current liabilities 89,151

93,868 Long-term debt 712 22,173 Deferred income taxes 59,052

45,152 Other noncurrent liabilities 18,292 29,023 Shareholders'

equity 429,072 420,416 ------- ------- Total liabilities and

shareholders' equity $596,279 $610,632 -------- -------- Tredegar

Corporation Condensed Consolidated Statement of Cash Flows (In

Thousands) (Unaudited) Year Ended December 31 ----------- 2009 2008

--- --- Cash flows from operating activities: Net income (loss)

$(1,353) $28,936 Adjustments for noncash items: Depreciation 39,877

43,068 Amortization of intangibles 120 123 Goodwill impairment

charge 30,559 - Deferred income taxes 6,771 22,183 Accrued pension

income and postretirement benefits (2,654) (4,426) Loss on asset

impairments and divestitures 1,005 10,136 Gain on the write-up of

an investment accounted for under the fair value method (e) (5,100)

(5,600) Gain on sale of assets (3,462) (3,083) Changes in assets

and liabilities, net of effects of acquisitions and divestitures:

Accounts and notes receivables 18,449 (678) Inventories 2,200

13,374 Income taxes recoverable 8,533 (12,092) Prepaid expenses and

other 1,209 (1,873) Accounts payable and accrued expenses 7,023

(18,900) Other, net 38 4,238 --- ----- Net cash provided by

operating activities 103,215 75,406 ------- ------ Cash flows from

investing activities: Capital expenditures (including settlement of

related accounts payable of $1,709 in 2009 and net of accounts

payable of $1,709 in 2008) (35,851) (19,235) Proceeds from the sale

of the aluminum extrusions business in Canada (net of cash included

in sale and transaction costs) - 23,407 Proceeds from the sale of

assets and property disposals 4,146 4,691 Investments - (5,391) ---

------ Net cash provided by (used in) investing activities (31,705)

3,472 ------- ----- Cash flows from financing activities: Dividends

paid (5,427) (5,447) Debt principal payments (21,539) (84,489)

Borrowings - 25,000 Repurchases of Tredegar common stock (including

settlement of payable of $3,368 in 2008) (1,523) (19,792) Proceeds

from exercise of stock options and other 245 4,069 --- ----- Net

cash used in financing activities (28,244) (80,659) ------- -------

Effect of exchange rate changes on cash 1,422 (461) ----- ----

Increase (decrease) in cash and cash equivalents 44,688 (2,242)

Cash and cash equivalents at beginning of period 45,975 48,217

------ ------ Cash and cash equivalents at end of period $90,663

$45,975 ------- ------- Selected Financial Measures (In Millions)

(Unaudited) For the Twelve Months Ended December 31, 2009

----------------------- Film Aluminum Products Extrusions Total

-------- ---------- ----- Operating profit from continuing ongoing

operations $64.4 $(6.5) $57.9 Allocation of corporate overhead

(12.9) (1.0) (13.9) Add back depreciation and amortization from

continuing operations 32.4 7.6 40.0 ---- ---- ---- Adjusted EBITDA

from continuing operations (g) $83.9 $0.1 $84.0 ----- ---- -----

Selected balance sheet and other data as of December 31, 2009: Net

debt (cash) (h) $(89.5) Shares outstanding 33.9 Notes to the

Financial Tables --------------------------------------- (a) Plant

shutdowns, asset impairments, restructurings and other in the

fourth quarter of 2009 include: -- A pretax charge of $1.0 million

for an asset impairment in Film Products; -- A pretax gain of

$640,000 related to the sale of land at our aluminum extrusions

manufacturing facility in Newnan, Georgia (included in "Other

income (expense), net" in the condensed consolidated statements of

income); -- Pretax gains of $547,000 associated with Aluminum

Extrusions for timing differences between the recognition of

realized losses on aluminum futures contracts and related revenues

from the delayed fulfillment by customers of fixed-price forward

purchase commitments (included in "Cost of goods sold" in the

condensed consolidated statements of income); -- Pretax charges of

$463,000 for severance and other employee-related costs in

connection with restructurings in Film Products ($181,000),

Aluminum Extrusions ($64,000) and corporate headquarters ($218,000,

included in "Corporate expenses, net" in the net sales and

operating profit by segment table); and -- A pretax charge of

$345,000 related to expected future environmental costs at our

aluminum extrusions manufacturing facility in Newnan, Georgia

(included in "Cost of goods sold" in the condensed consolidated

statements of income). Plant shutdowns, asset impairments,

restructurings and other in 2009 include: -- Pretax charges of $2.1

million for severance and other employee-related costs in

connection with restructurings in Film Products ($1.3 million),

Aluminum Extrusions ($433,000) and corporate headquarters

($396,000, included in "Corporate expenses, net" in the net sales

and operating profit by segment table); -- A pretax charge of $1.0

million for an asset impairment in Film Products; -- Pretax losses

of $952,000 associated with Aluminum Extrusions for timing

differences between the recognition of realized losses on aluminum

futures contracts and related revenues from the delayed fulfillment

by customers of fixed-price forward purchase commitments (included

in "Cost of goods sold" in the condensed consolidated statements of

income); -- A pretax gain of $640,000 related to the sale of land

at our aluminum extrusions manufacturing facility in Newnan,

Georgia (included in "Other income (expense), net" in the condensed

consolidated statements of income); -- Pretax gain of $275,000 on

the sale of equipment (included in "Other income (expense), net" in

the condensed consolidated statements of income) from a previously

shutdown film products manufacturing facility in LaGrange, Georgia;

-- A pretax gain of $175,000 on the sale of a previously shutdown

aluminum extrusions manufacturing facility in El Campo, Texas

(included in "Other income (expense), net" in the condensed

consolidated statements of income); -- A pretax gain of $149,000

related to the reversal to income of certain inventory impairment

accruals in Film Products; and -- A pretax net charge of $69,000

(included in "Cost of goods sold" in the condensed consolidated

statements of income) related to adjustments of future

environmental costs expected to be incurred by Aluminum Extrusions.

Plant shutdowns, asset impairments and restructurings in the fourth

quarter of 2008 include: -- Pretax charges of $7.2 million for

asset impairments in Film Products; -- A pretax gain of $583,000

related to the sale of land rights and related improvements at Film

Products facility in Shanghai, China (included in "Other income

(expense), net" in the condensed consolidated statements of

income); and -- A pretax charge of $72,000 related to expected

future environmental costs at Aluminum Extrusions facility in

Newnan, Georgia (included in "Cost of goods sold" in the condensed

consolidated statement of income). Plant shutdowns, asset

impairments and restructurings in 2008 include: -- Pretax charges

of $9.7 million for asset impairments in Film Products; -- Pretax

charges of $2.7 million for severance and other employee-related

costs in connection with restructurings in Film Products ($2.2

million) and Aluminum Extrusions ($510,000); -- A pretax gain of

$583,000 related to the sale of land rights and related

improvements at Film Products facility in Shanghai, China (included

in "Other income (expense), net" in the condensed consolidated

statements of income); and -- A pretax charge of $177,000 related

to expected future environmental costs at Aluminum Extrusions

facility in Newnan, Georgia (included in "Cost of goods sold" in

the condensed consolidated statements of income). (b) Goodwill

impairment charge of $30.6 million ($30.6 million after taxes) was

recognized in Aluminum Extrusions in the first quarter of 2009 upon

completion of an impairment analysis performed as of March 31,

2009. This non-cash charge resulted from the estimated adverse

impact on the business unit's fair value of possible future losses

and the uncertainty of the amount and timing of an economic

recovery. (c) Comprehensive income (loss), defined as net income

(loss) and other comprehensive income (loss), was income of $14.8

million in the fourth quarter of 2009 and a loss of $67.9 million

in the fourth quarter of 2008. Comprehensive income (loss) was

income of $13.7 million in 2009 and a loss of $54.7 million in

2008. Other comprehensive income (loss) includes changes in foreign

currency translation adjustments, unrealized gains and losses on

derivative financial instruments and prior service cost and net

gains or losses from pension and other postretirement benefit plans

arising during the period and the related amortization of these

prior service cost and net gains or losses recorded net of deferred

taxes directly in shareholders' equity. The comprehensive loss for

the fourth quarter and full year of 2008 related to the significant

reduction in the funded status of our pension plans from 2007 to

2008. (d) Gain on the sale of investments in Theken Spine and

Therics, LLC includes the receipt of a contractual earn-out payment

of $1.8 million in the fourth quarter of 2009 and a post-closing

contractual adjustment of $150,000 in the first quarter of 2009.

The 2008 gain on sale of $1.5 million was received at the closing

of the sale of the investments. These amounts are included in

"Other income (expense), net" in the condensed consolidated

statements of income. AFBS (formerly Therics, Inc.) received these

investments in 2005, when substantially all of the assets of AFBS,

Inc., a wholly-owned subsidiary of Tredegar, were sold or assigned

to a newly-created limited liability company, Therics, LLC,

controlled and managed by an individual not affiliated with

Tredegar. (e) Gain on sale of corporate assets in 2009 includes a

realized gain on the sale of corporate real estate ($404,000) in

the first quarter of 2009. Gain on the sale of corporate assets in

2008 includes a realized gain related to the sale of equity

securities ($509,000) and a realized gain on the sale of corporate

real estate ($492,000), both in the third quarter of 2008. These

gains are included in "Other income (expense), net" in the

condensed consolidated statement of income. The unrealized gain

from the write-up of an investment accounted for under the fair

value method of $5.1 million in 2009 and $5.6 million in 2008 is

also included in "Other income (expense), net" in the condensed

consolidated statements of income. The unrealized gain in 2009 is

attributed to the appreciation of our ownership interest upon the

investee, a drug delivery company, entering into an exclusive

licensing agreement that includes upfront and potential milestone

payments. The write-up in 2008 was based on the valuation of

Tredegar's investment implied from the term sheet of a new round of

equity financing for the investee. Income taxes for 2009 include

the recognition of valuation allowances of $2.1 million (which

includes partial reversals of $476,000 and $1.2 million recognized

in the third and fourth quarters, respectively) related to expected

limitations on the utilization of assumed capital losses on certain

investments. Income taxes for 2008 include the partial reversal of

a valuation allowance recognized in the third quarter of 2007 of

$1.1 million that originally related to expected limitations on the

utilization of assumed capital losses on certain investments. (f)

On February 12, 2008, Tredegar sold its aluminum extrusions

business in Canada for a purchase price of approximately $25.0

million to an affiliate of H.I.G. Capital. The purchase price was

subject to adjustment based upon the actual working capital of the

business at the time of sale. All historical results for this

business have been reflected as discontinued operations in the

accompanying financial tables. The components of income (loss) from

discontinued operations are presented below: Fourth Quarter Ended

Year Ended December 31 December 31 ----------- ----------- (In

thousands) 2009 2008 2009 2008 --- --- --- --- Income (loss) from

operations before income taxes $- $- $- $(391) Income tax cost

(benefit) on operations - - - (98) --- --- --- --- - - - (293) ---

--- --- ---- Loss associated with asset impairments and disposal

activities - - - (1,337) Income tax cost (benefit) on asset

impairments and costs associated with disposal activities - (225) -

(925) --- --- --- --- - 225 - (412) --- --- --- --- Income (loss)

from discontinued operations $- $225 $- $(705) --- ---- --- -----

(g) Adjusted EBITDA for the twelve months ended December 31, 2009,

represents income from continuing operations before interest;

taxes; depreciation; amortization; unusual items, goodwill

impairments and losses associated with plant shutdowns, asset

impairments and restructurings; gains or losses from the sale of

assets; investment write-downs or write-ups; charges related to

stock option awards accounted for under the fair value-based

method; and other items. Adjusted EBITDA is not intended to

represent net income or cash flow from operations as defined by

GAAP and should not be considered as either an alternative to net

income (as an indicator of operating performance) or to cash flow

(as a measure of liquidity). Tredegar uses Adjusted EBITDA as a

measure of unlevered (debt-free) operating cash flow. We also use

it when comparing relative enterprise values of manufacturing

companies and when measuring debt capacity. When comparing the

valuations of a peer group of manufacturing companies, we express

enterprise value as a multiple of Adjusted EBITDA. We believe

Adjusted EBITDA is preferable to operating profit and other GAAP

measures when applying a comparable multiple approach to enterprise

valuation because it excludes the items noted above, measures of

which may vary among peer companies. (h) Net debt (cash) is

calculated as follows (in millions): Debt $1.2 Less: Cash and cash

equivalents (90.7) ----- Net debt (cash) $(89.5) ------ Net debt or

cash is not intended to represent debt or cash as defined by GAAP.

Net debt or cash is utilized by management in evaluating the

company's financial leverage and equity valuation and the company

believes that investors also may find net debt or cash to be

helpful for the same purposes. DATASOURCE: Tredegar Corporation

CONTACT: Kevin A. O'Leary, +1-804-330-1102, Fax, +1-804-330-1777, ,

Web Site: http://www.tredegar.com/

Copyright

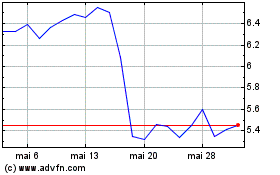

Tredegar (NYSE:TG)

Gráfico Histórico do Ativo

De Dez 2024 até Jan 2025

Tredegar (NYSE:TG)

Gráfico Histórico do Ativo

De Jan 2024 até Jan 2025