Alphamin Announces an Initial Inferred Mineral Resource for the Gecomines Prospect, Bisie Tin Project, Democratic Republic of...

26 Novembro 2013 - 3:01PM

Marketwired Canada

Highlights

-- Drilling at Gecomines has outlined an Inferred Mineral Resource of 4.0

million tonnes @ 3.5%Sn for 141,200 tonnes of contained tin at a 0.25%

cut-off

-- The Inferred Resource was defined over 400m strike to a depth of 220m

and is open at depth

-- Tin mineralisation has a strong chute geometry with high grade chutes

interpreted to plunge to the north

-- Best intercepts were reported from the deepest holes drilled to date

-- Preliminary Economic Assessment (PEA) has been suspended pending results

from additional deep drilling which still needs to be conducted

-- Monitoring project site security situation to resume drilling work

Alphamin Resources Corp. (TSX VENTURE:AFM) ("Alphamin" or the "Company") is

pleased to announce a maiden Inferred Mineral Resource at the Gecomines target

on its wholly owned Bisie Tin Prospect (Bisie Project) in east central

Democratic Republic of the Congo (DRC).

The Gecomines Target Inferred Mineral Resource currently comprises 4.0 million

tonnes @ 3.5%Sn for 141,200 tonnes of contained tin (at 0.25% Sn cut-off) as

shown in Table 1. Drilling was focused on 400m of the Gecomines target where

holes were drilled on a grid of approximately 50m x 50m down to depths of 220m

below surface. The best results were reported from the four deepest holes

drilled to date.

Table 1: Gecomines Mineral Resource at 0.25% Sn Cut-Off Grade, 26 November 2013

---------------------------------------------------------------------------

Tonnes Sn Sn Tonnes Cu Zn Pb Ag

Category (Million) % (Thousand) % % % g/t

---------------------------------------------------------------------------

Inferred 4.0 3.5 141.2 0.27 0.12 0.01 2.2

Total 4.0 3.5 141.2 0.27 0.12 0.01 2.2

---------------------------------------------------------------------------

Notes:

1. All tabulated data has been rounded and as a result minor computational

errors may occur

2. Mineral Resources which are not Mineral Reserves have no demonstrated

economic viability.

3. Alphamin has a 100 percent interest in the Bisie Project. Accordingly,

the Gross and Net Attributable Inferred Mineral Resources are the same.

The Mineral Resource was prepared by an independent consulting company, The MSA

Group (MSA), of Johannesburg, South Africa and was estimated using The Canadian

Institute of Mining, Metallurgy and Petroleum (CIM) Best Practice Guidelines

(2003). The Mineral Resource is reported in accordance with the 2010 CIM

Definition Standards which have been incorporated by reference into National

Instrument 43-101 - Standards of Disclosure for Mineral Projects (NI 43-101).

The Mineral Resource is classified into the Inferred category as shown in Table

1. A technical report prepared in compliance with NI-43-101 with respect to the

initial Mineral Resource estimate will be filed on www.sedar.com.

The Mineral Resource was constrained to a maximum depth of approximately 250m

below surface, the high grade mineralisation being open at depth. The top 50m

has been depleted by artisanal mining activity and any mineralisation remaining

in this area was not included in the Mineral Resource.

The Mineral Resource estimate was based on Sn, Cu, Pb, Zn and Ag assays and

density measurements from 28 of the 37 diamond holes drilled at Gecomines. Drill

holes not included in the estimate were within the top 50m depleted zone or

drilled to the north and south of the main zone of mineralisation. A three

dimensional grade block model was created using Ordinary Kriging. Figure 1 shows

the general geometry of the mineralisation while Table 2 below details

analytical and modelling methods.

To view Figure 1 please click the following link:

http://media3.marketwire.com/docs/AMFig1.pdf

The Company will now continue drilling below the high grade mineralisation

intersected at Gecomines to confirm grade trends at depth. The current high

grade Inferred Mineral Resource was greatly influenced by the three deepest

holes. Further drilling will also test the extent of mineralisation at the

Golgotha target situated 750m to the south.

Preliminary Economic Assessment (PEA)

The PEA has been suspended until a revised geological model has been constructed

that will include representative intersections of the mineralisation anticipated

to be intersected below the current level of drilling. It is expected that these

results will have a material impact on the underground mine design and optimal

stoping method.

Initial work has concluded that a non-selective bulk underground mining method

will be required, which can be expected to deliver mine grades substantially

below those stated above.

Security

The Company has experienced delays in exploration and drilling since August 2013

when all staff were evacuated due to hostile rebel activities in the immediate

surrounds. The Company field camp was raided on 9 November by a group of

villagers who caused damage to company equipment and assets. The Company will

assess the security situation on site and work will only resume once calm has

been restored to the area and staff can return to the project site safely.

ON BEHALF OF THE BOARD OF DIRECTORS

Klaus Eckhof, Chief Executive Officer

Neither the TSX Venture Exchange nor its regulation services provider (as that

term is defined in the policies of the TSX Venture Exchange) accepts

responsibility for the adequacy or accuracy of this News Release.

CAUTION REGARDING FORWARD LOOKING STATEMENTS

Information in this news release that is not a statement of historical fact

constitutes forward-looking information. Such forward-looking information

includes statements regarding the Company's planned exploration programs. Actual

results, performance or achievements of the Company may vary from the results

suggested by such forward-looking statements due to known and unknown risks,

uncertainties and other factors. Such factors include, among others, that the

business of exploration for tin and other precious and base minerals involves a

high degree of risk and is highly speculative in nature; few properties that are

explored are ultimately developed into producing mines; geological factors; the

actual results of current and future exploration; changes in project parameters

as plans continue to be evaluated, as well as those factors disclosed in the

Company's publicly filed documents.

There can be no assurance that any mineralisation that is discovered will be

proven to be economic, or that future required regulatory licensing or approvals

will be obtained. However, the Company believes that the assumptions and

expectations reflected in the forward-looking information are reasonable.

Assumptions have been made regarding, among other things, the Company's ability

to carry on its exploration activities, the sufficiency of funding, the timely

receipt of required approvals, the price of tin and other precious and base

metals, that the Company will not be affected by adverse political events, the

ability of the Company to operate in a safe, efficient and effective manner and

the ability of the Company to obtain further financing as and when required and

on reasonable terms. Readers should not place undue reliance on forward-looking

information.

Alphamin does not undertake to update any forward-looking information, except as

required by applicable laws.

COMPETENT PERSON'S STATEMENT

The Mineral Resource estimate has been completed by Mr. J.C. Witley (BSc Hons,

GDE) who is a geologist with 25 years' experience in base and precious metals

exploration and mining as well as Mineral Resource evaluation and reporting. He

is a Principal Resource Consultant for The MSA Group (an independent consulting

company), is a member in good standing with the South African Council for

Natural Scientific Professions (SACNASP) and is a Member of the Geological

Society of South Africa (GSSA).Mr Witley has the appropriate relevant

qualifications and experience to be considered a "Qualified Person" for the

style and type of mineralisation and activity being undertaken as defined in

National Instrument 43-101 Standards of Disclosure of Mineral Projects.

Table 2: Summary of resource estimate and reporting criteria

---------------------------------------------------------------------------

Drilling All drillholes were diamond drill cored and drilled from

techniques surface (mostly NQ) at angles of between -60 degrees and

-75 degrees.

In the Mineral Resource area, 28 of the 37 drillholes

completed were used for the grade estimate, four of the

holes intersected mineralisation to the north and south of

the high grade zone and five of the shallow drillholes

intersected artisanal workings. The data from these nine

holes were not used for grade estimation.

---------------------------------------------------------------------------

Logging All of the drillholes were geologically logged by

qualified geologists. The logging was of an appropriate

standard for grade estimation.

---------------------------------------------------------------------------

Drill sample Core recovery in the mineralised zones was observed to be

recovery very good and was on average 95%. Five of the shallow

drillholes intersected artisanal workings and so recovery

of the high grade mineralisation was poor and therefore

the data from these holes were not used for grade

estimation.

---------------------------------------------------------------------------

Sampling Half core samples were collected continuously through the

methods mineralised zones after being cut longitudinally in half

using a diamond saw. Drillhole samples were taken at

nominal 1 m intervals, which were adjusted to smaller

intervals in order to target the vein zones. Lithological

contacts were honoured during the sampling. MSA's

observations indicated that the routine sampling methods

were of a high standard and suitable for evaluation

purposes.

---------------------------------------------------------------------------

Quality of The assays were conducted at ALS Chemex in Johannesburg

assay data and where samples were analyzed using fused disc ME-XRF05

laboratory conducted on a pressed pellet with 10% precision and an

tests upper limit of 10 000ppm. Over limit samples were sent to

Vancouver for ME-XRF10 which uses a Lithium Borate 50:50

flux with an upper detection limit of 60% and precision of

5%.

ME-ICP61, HF, HNO3, HCL04 and HCL leach with ICP-AES

finish was used for 33 elements including base metals. ME-

OG62 a four acid digestion was used on ore grade samples

for Pb, Zn, Cu & Ag.

External quality assurance of the laboratory assays for

the Alphamin samples was monitored by the insertion of:

- Blank samples collected from quartz vein on site at a

rate of approximately 3% of the total sample set.

- Field duplicates consisting of quarter core on

approximately 4% of the total sample set.

- Certified reference materials (CRM's): Four CRMs were

used. Combined, these formed approximately 3% of the

total sample set.

The QAQC measures used by Alphamin revealed the following:

- The high grade CRM (31.42% Sn) indicated that an over-

assay of approximately 8% may have occurred. The lower

grade CRMs (less than 2% Sn) indicated that the Sn and Cu

assays were accurate consistently within two standard

deviations of the accepted CRM value.

- The field duplicates confirmed the nuggetty nature of the

tin mineralisation. The majority of the duplicate assays

were within 20% of the field sample.

- Blank samples indicated that no significant contamination

occurred for most of the programme. Seven blank assays

returned Sn values of between 0.005% and 0.02%, which is

not considered material to the project.

---------------------------------------------------------------------------

Verification of MSA observed the mineralisation in the cores and compared

sampling and it with the assay results. MSA found that the assays

assaying generally agreed with the observations made on the core.

MSA took ten quarter core field duplicates for independent

check assay, which confirmed the original sample assays

within reasonable limits for this style of mineralisation.

---------------------------------------------------------------------------

Location of All of the Bisie surface drillhole collars have been

data points surveyed by a qualified surveyor using a differential GPS.

Down-hole survey's were completed for all of the holes

drilled at Gecomines.

---------------------------------------------------------------------------

Tonnage factors Specific gravity determinations were made for the

(in situ bulk drillhole samples using the Archimedes principal of weight

densities) in air versus weight in water. Where no density data were

available, a regression equation was applied. Specific

gravity was interpolated into the block model using

Ordinary Kriging.

---------------------------------------------------------------------------

Data density Drillholes intersected the Mineral Resource at between

and approximately 50 m by 50 m and 100 m by 100 m spacing in

distribution the plane of mineralisation.

---------------------------------------------------------------------------

Database Data were stored in an Excel database. MSA completed spot

integrity checks on the database and is confident that the Alphamin

database is an accurate representation of the original

data collected.

---------------------------------------------------------------------------

Dimensions The area defined as a Mineral Resource extends

approximately 400 m along strike by 200 m on dip. The

Mineral Resource is between approximately 10 m and 20 m

thick, although narrower zones occur to the north.

---------------------------------------------------------------------------

Geological The mineralised intersections in drill core are clearly

interpretation discernible. The Mineral Resource is interpreted to occur

as two sub-parallel locally complex vein systems of

mineralisation dipping 65 degrees to the east, in places

separated by a barren zone several metres wide. The

mineralised zones and intermittent waste middling are

composed of chlorite schist that is the result of intense

alteration that may represent a distinct stratigraphic

interval. The Mineral Resource is affected by a number of

faults that are sub-parallel to the mineralisation causing

local displacement. The precise locations of faults have

not been determined.

---------------------------------------------------------------------------

Domains The mineralisation was modelled as a thick slab containing

irregular vein style mineralisation. In places a waste

interval was defined by Sn grades of less than 0.25%. A

hard boundary was used to select data for estimation in

order to honour the sharp nature of vein boundaries.

---------------------------------------------------------------------------

Compositing Sample lengths were composited to 2 m.

---------------------------------------------------------------------------

Statistics and The coefficient of variation for Sn composites is between

variography 1.5 and 2.1, the histograms being positively skewed.

Normal Scores variograms were calculated in the plane of

the mineralisation layering, down-hole and across strike.

Variogram ranges were 120 m in the in-plane direction and

10 m across strike.

---------------------------------------------------------------------------

Top or bottom Top cuts were applied to outlier values that were above

cuts for grades breaks in the cumulative probability plot.

---------------------------------------------------------------------------

Data clustering Drillhole intersections were not clustered, the grid being

approximately regular.

---------------------------------------------------------------------------

Block size 4 mN by 40 mE by 40mRL three dimensional block models as

optimised using a Kriging Neighbourhood Analysis. The

blocks were rotated into the plane of mineralisation prior

to estimation.

---------------------------------------------------------------------------

Grade The accumulation of grade and density were estimated using

estimation Ordinary Kriging. Estimation parameters were optimised

using a Kriging Neighbourhood Analysis.

A minimum number of 8 and a maximum of 16 two metre

composites were required to be selected within 120 m of a

block in order to achieve an estimate. Grades were

extrapolated in the plane of the mineralisation for a

maximum distance of 40 m from the nearest drillhole

intersection, this being considered by MSA to be the limit

of reasonable geological interpretation for this style of

mineralisation, it being possible that the mineralisation

could terminate abruptly.

---------------------------------------------------------------------------

Resource The mineralisation was classified as Inferred Mineral

Classification Resources if block estimates were achieved with the

required minimum number of samples within 40 m in the dip

direction of the nearest borehole. In the strike

directions half the distance between the high grade

intersections and peripheral lower grade intersections was

applied, this being less than 40 m.

---------------------------------------------------------------------------

Mining Cuts A minimum true thickness of 2 m was applied. The

considerable thickness and steep dip implies that the

Mineral Resource can be extracted using established

underground mining methods.

---------------------------------------------------------------------------

Metallurgical The tin mineralisation occurs as cassiterite, an oxide of

factors or tin (SnO2). The Cu, Zn and Pb mineralisation occurs as

assumptions sulphides. Each of these minerals is amenable to standard

processing techniques for each metal.

---------------------------------------------------------------------------

Legal Aspects Alphamin through its wholly owned DRC subsidiary, Mining

and Tenure and Processing Congo Sprl, has a "Certificat de

Recherches" for PR 5266 valid to November 2014 after which

it will be renewed with a 50% reduction on the licence

area

---------------------------------------------------------------------------

Audits and The following review work was completed by MSA:

reviews

- Inspection of approximately 25% of the Alphamin cores

used in the Mineral Resource estimate

- Database spot check

- Inspection of drill sites

- Independent check sampling

---------------------------------------------------------------------------

FOR FURTHER INFORMATION PLEASE CONTACT:

Alphamin Resources Corp.

Level 3, Gotthardstrasse 20, CH-6304

Zug, Switzerland

Tel: +41 41 711 02 81

www.alphaminresources.com

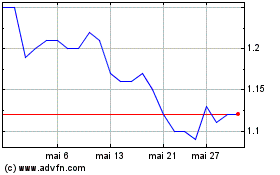

Alphamin Resources (TSXV:AFM)

Gráfico Histórico do Ativo

De Mai 2024 até Jun 2024

Alphamin Resources (TSXV:AFM)

Gráfico Histórico do Ativo

De Jun 2023 até Jun 2024