UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM SD

SPECIALIZED DISCLOSURE REPORT

JOHNSON CONTROLS INTERNATIONAL PLC

__________________________________________

(Exact name of registrant as specified in its charter) | | | | | | | | |

| | |

| Ireland | 001-13836 | 98-0390500 |

______________________________________ (State or other jurisdiction | ____________________ (Commission | ____________________________ (I.R.S. Employer |

| of incorporation or organization) | File Number) | Identification No.) |

| | |

One Albert Quay

Albert Quay, Cork Ireland |

_____________________________________________________________ (Address of principal executive offices) |

| | | | | | | | |

| Corporate Secretary |

| 353-21-423-5000 |

(Name and telephone number, including area code,

of the person to contact in connection with this report.) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

[x] Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023.

Section 1 Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Johnson Controls International plc (the "Company") has filed as an exhibit to this Specialized Disclosure Form a Conflict Minerals Report in accordance with the requirements of Rule 13p-1 of the Securities Exchange Act of 1934. The Conflict Minerals Report is also available on the Company’s website at www.johnsoncontrols.com/corporate-sustainability/reporting-and-policies.

Item 1.02 Exhibit

See Item 3.01 of this Form.

Section 3 Exhibits

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned. | | | | | | | | | | | | | | | | | |

| | | | | |

| | JOHNSON CONTROLS INTERNATIONAL PLC | |

| | | | | |

| Date: May 29, 2024 | | By: | /s/ Richard J. Dancy | |

| | | Name: | Richard J. Dancy | |

| | | Title: | Vice President and Corporate Secretary |

| | | | | |

| | | | | |

Johnson Controls International plc

Conflict Minerals Report

For the Calendar Year Ended December 31, 2023

I. Background

This is the Conflict Minerals Report (“Report”) of Johnson Controls International plc for calendar year 2023 in accordance with Rule 13p-1 under the Securities Exchange Act of 1934 (the “Rule”). As used in this Report, and except where the context otherwise requires, the "Company", "Johnson Controls", “we” and “our” refer to Johnson Controls International plc and its majority-owned subsidiaries and variable interest entities that are required to be consolidated.

The term “conflict mineral” is defined to include cassiterite, columbite-tantalite, gold, and wolframite and their derivatives, including tantalum, tin and tungsten (collectively, “3TG”), regardless of their source.

The term "Covered Countries" is defined as the Democratic Republic of the Congo (the “DRC”) and the countries adjoining the Democratic Republic of the Congo.

II. Company Overview

Johnson Controls International plc, headquartered in Cork, Ireland, is a global leader in smart, healthy and sustainable buildings, serving a wide range of customers in more than 150 countries. The Company’s products, services, systems and solutions advance the safety, comfort and intelligence of spaces to serve people, places and the planet. The Company's commitment to sustainability dates back to its roots in 1885, with the invention of the first electric room thermostat. The Company is committed to helping its customers win and creating greater value for all of its stakeholders through its strategic focus on buildings. Additional information about the Company and its core businesses may be obtained by accessing Johnson Controls’ corporate website at: www.johnsoncontrols.com. A copy of this Report can be found at: http://www.johnsoncontrols.com/corporate-sustainability/reporting-and-policies.

III. Product Overview

The Company is a global leader in engineering, manufacturing, and commissioning building products and systems, including residential and commercial HVAC equipment, industrial refrigeration systems, controls, security systems, fire-detection systems and fire-suppression solutions. The Company further serves customers by providing technical services, including maintenance, management, repair, retrofit and replacement of equipment (in the HVAC, industrial refrigeration, security and fire-protection space) and energy-management consulting. The Company's OpenBlue digital software platform enables enterprises to better manage their physical spaces by combining the Company's building products and services with cutting-edge technology and digital capabilities to enable data-driven “smart building” services and solutions. The Company partners with customers by leveraging its broad product portfolio and digital capabilities powered by OpenBlue, together with its direct channel service and solutions capabilities, to deliver outcome-based solutions across the lifecycle of a building that address customers’ needs to improve energy efficiency, enhance security, create healthy environments and reduce greenhouse gas emissions.

IV. Supply Chain Description

The Company is committed to the responsible sourcing of conflict minerals and is an active member of the Responsible Minerals Initiative (“RMI”). Founded in 2008 by members of the Responsible Business Alliance and the Global e-Sustainability Initiative, the RMI has grown into one of the most utilized and respected resources for companies from a range of industries addressing responsible mineral sourcing issues in their supply chains.

The Company encourages its suppliers to source from smelters or refiners that follow the Responsible Minerals Assurance Process ("RMAP") assessment protocols.

As a large multinational company, the Company has a complex, multi-tiered supply chain. The products that the Company manufactures or contracts to manufacture are typically highly engineered, complex and contain thousands of parts from a vast network of globally dispersed suppliers.

As a downstream consumer with many tiers in its supply chain, the Company generally does not have a direct relationship with smelters and refiners. Thus, the Company must rely on its direct suppliers to provide information on the origin of any conflict minerals contained in the components and parts supplied to it.

V. Reasonable Country of Origin Inquiry

A.Process Summary

The Company’s Reasonable Country of Origin Inquiry (“RCOI”) for calendar year 2023 was designed to determine whether the conflict minerals necessary to the functionality or production of a product manufactured (or contracted to be manufactured) by the Company originated in the Covered Countries, or are from recycled or scrap sources. The Company established a system of controls designed to promote transparency over the conflict minerals in its supply chain. The Company regularly conducts an analysis of its products and supply chain, and, accordingly, the Company has not limited its review to only products that have the potential of containing conflict minerals. The Company identified suppliers that were considered in-scope and subject to the RCOI, primarily consisting of first-tier suppliers delivering parts and other direct materials to the Company's factories for use in the manufacturing of the Company's products (“In-Scope Suppliers”). In addition, the Company identified select In-Scope Suppliers as high-risk for additional scrutiny. Through communications with these In-Scope Suppliers, the Company attempted to identify smelters and refiners of conflict minerals that may be utilized in products supplied to the Company.

Due to the complexity of the Company’s supply chain, the Company relied on its first-tier suppliers to provide information on the origin of conflict minerals potentially present in components and parts. The Company gathers information from its suppliers regarding conflict minerals annually. The Company sends out an interactive survey to identified In-Scope Suppliers containing the RMI Conflict Minerals Reporting Template or a Supplier Substances Declaration template referred to herein collectively as the “Survey” or “Surveys” to In-Scope Suppliers to gather information on the chain of custody of the conflict minerals potentially included in the Company’s products. During 2023, depending on the business, the Company focused on the following: high-spend suppliers, suppliers delivering a significant number of different parts

or suppliers delivering products with a high potential of having 3TG present in materials provided to the Company.

The Company elected to utilize the Surveys as well as tracking tools to facilitate its RCOI. The questions on the Surveys included, but were not limited to, the use of conflict minerals and their necessity to product functionality or production, the origin of such conflict minerals, and whether smelters or refiners have been validated as conformant with RMAP standards. The Company proactively communicates with In-Scope Suppliers, notifying them of the RCOI and the Company’s expectations of its suppliers and provides detailed instructions to assist with the completion of the Surveys.

Further information is available via the Company’s website at http://www.johnsoncontrols.com/suppliers/sustainability/conflict-minerals.

In addition to the RCOI efforts described above, the Company undertook the following measures to determine mine or country of origin:

•The Company considered the following supply base categories as in-scope for RCOI purposes: manufactured products and, products contracted to be manufactured.

•The Company provided instructions and training to its In-Scope Suppliers regarding the relevant requirements of the Rule and its obligations under the Rule and reiterated the Company’s expectation that suppliers cooperate to support the Company’s conflict minerals compliance efforts. Refer to the “Supplier Engagement and Training” section of this Report for more information.

•The Company required each In-Scope Supplier to provide information regarding the use of conflict minerals from their suppliers, who in turn, were expected and encouraged to solicit that information from their next tier of suppliers.

•The responses received from the Company’s In-Scope Suppliers about the country of origin of any conflict minerals necessary to functionality or production were reviewed for reasonableness and the Company followed up as necessary.

B.RCOI Results

There were 4,481 In-Scope Suppliers for calendar year 2023, which represented 35% of the Company’s total direct suppliers assessed to potentially have 3TG in their products. During 2023, the Company sent communications to 100% of its In-Scope Suppliers, notifying them of the RCOI.

Of the In-Scope Suppliers surveyed, the overall response rate was 70%, including 2,425 responses that were received and accepted (representing 54% of the suppliers surveyed). The Company considers a response as received and accepted when a completed Survey or reasonable confirmation has been returned to the Company and the Survey has been reviewed by the Company to confirm that it has been properly completed. Below are the received and accepted RCOI survey results:

| | | | | |

| RCOI Survey Results |

| No 3TG | 67% |

| Acknowledged 3TG Sourced from Covered Countries | 19% |

| Acknowledged 3TG Not Sourced from Covered Countries | 14% |

C.Improvement Measures to Be Taken

The Company continues to look for ways to improve its processes and to mitigate any risk that conflict minerals in its products could benefit armed groups in the Covered Countries. Specifically, the Company is undertaking, and will continue to undertake, the following steps:

•Engage with those In-Scope Suppliers that have not responded to the Company’s initial request for conflict minerals information.

•Reconsider supply arrangements and potentially implement remedies available to the Company for suppliers that refuse to cooperate with the Company’s compliance efforts or do not conduct conflict-free sourcing from Covered Countries.

•Continue to improve training initiatives to increase the level of awareness within the Company and at its suppliers.

•Continue to follow up with identified non-conformant smelters or refiners conducting business with In-Scope Suppliers to achieve conformant status and participate in the RMAP.

•As an RMI active member, the Company validates the aggregation of the Company’s smelter and refiner database data against the latest RMI RCOI database of smelters and refiners to improve the determination process of the location accuracy and RMI status of the Company's smelters and refiners.

Refer to the “Risk Mitigation Measures” section of this Report for further actions taken by the Company to mitigate risk related to conflict minerals in the Company's supply chain.

VI. Conflict Minerals Due Diligence

A. Compliance Framework

Framework Design and Overview

The Company designed a compliance framework that conforms to the primary principles of the internationally recognized due diligence framework developed by the Organisation for Economic Co-operation and Development (“OECD”) as set forth in the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas: Third Edition, and the related supplements on tin, tungsten, tantalum, and gold. The Company’s compliance framework included the following elements: 1) establish strong company management systems; 2) identify and assess risk in the supply chain; 3) design and implement a strategy to respond to identified risks; 4) access and use independent third-party audit of smelters’/refiners’ due diligence practices; and 5) report annually on supply chain due diligence.

1.Establish Strong Company Management Systems

Conflict Minerals Policy

The Company is committed to the responsible sourcing of conflict minerals and supports the humanitarian goal of ending violent conflict in the Covered Countries. Among other things, the Company’s corporate policy expresses that it continues to promote and encourage its suppliers to conduct conflict-free sourcing

from the Covered Countries, and to use responsible sourcing practices. The Company expects its suppliers to conduct due diligence on their respective supply chains and to support the Company's compliance with these rules. To the extent that a supplier refuses to cooperate with the Company’s compliance efforts or does not conduct conflict-free sourcing from the Covered Countries, the Company may reconsider its supply arrangement and implement available remedies. The Company’s Conflict Minerals Policy Statement is publicly available on the Company’s website at http://www.johnsoncontrols.com/corporate-sustainability/reporting-and-policies.

Internal Management System

The Company maintains an internal management system, where senior management, having the necessary expertise, knowledge and experience, oversees the supply chain country of origin inquiries and due diligence process. The Company continues to seek ways to address risk in its supply chain process through initiatives that often involve stakeholder engagement.

The Company maintains a Conflict Minerals Executive Steering Committee (“Steering Committee”) comprised of leaders from Procurement, Legal and Sustainability, with advisory support from Internal Audit. The Steering Committee oversees and supports the Company’s conflict minerals compliance. The Steering Committee meets at least annually to monitor compliance with the reporting requirements of the Rule.

System of Controls and Transparency

Due to the complexity of the Company’s supply chain, the Company relies on its first-tier suppliers to provide information on the origin of conflict minerals potentially present in materials supplied to the Company. The Company’s RCOI and due diligence processes are designed to gather information on the chain of custody of the necessary conflict minerals potentially included in the Company’s products.

Supplier Engagement and Training

The Company made available to all of its In-Scope Suppliers conflict minerals training materials that summarize the relevant requirements of the Rule as part of the instructions for completing the CMRT or through other training and instruction links on the Surveys, the Company’s obligations under the Rule, and reiterates the Company’s expectation that its suppliers cooperate to support conflict minerals compliance efforts.

The Company also provides the In-Scope Suppliers with instructions for responding to the survey and the Company’s Compliance Specialists have scripts to help explain the Company’s requests, and the reason behind the requests.

The Company publicly shares its position statement on conflict minerals through its Conflict Minerals Policy Statement. In addition, as the Company renews or enters into new agreements with suppliers with products that may contain conflict minerals, the Company includes a conflict minerals compliance provision within its standard terms and conditions for suppliers.

Internal Training

The Company has instructions and training designed to increase employee awareness and education about the relevant requirements of the Rule, the Company's obligations under the Rule, and the processes the Company uses to evaluate and respond to the risk of conflict minerals in our supply chain.

Records Management

The Company retains relevant conflict minerals documentation in accordance with its existing corporate retention policy and procedures.

Grievance Mechanism

The Company maintains a web- and telephone-based, 24-hour Integrity Helpline (http://www.johnsoncontrols.com/about-us/ethics-and-compliance), providing any interested party with a confidential reporting mechanism to communicate concerns regarding the Company’s supply chain or other matters. Our internal specialists track information relative to conflict minerals via this mechanism.

2.Identify and Assess Risk in the Supply Chain

The Company’s RCOI was designed to determine whether the conflict minerals necessary to the functionality or production of a product manufactured (or contracted to be manufactured) by the Company originated in the Covered Countries, or were from recycled or scrap sources. Through communications with the Company's suppliers, the Company attempted to identify smelters and refiners of conflict minerals that may be utilized in products supplied to the Company.

3.Design and Implement a Strategy to Respond to Identified Risks

The Company has established due diligence guidelines to be followed if the Company identifies a risk or red flag that a supplier sourced conflict minerals from the Covered Countries through a review of the received Survey. Where non-conformant smelters or refiners are identified, the Company will continue to follow-up with suppliers and directly with non-conformant smelters or refiners as described in Section VI(C) ("Risk Mitigation Measures") below.

4.Access and Use Independent Third-Party Audit of Smelters’/Refiners’ Due Diligence Practices

The Company encourages its suppliers to source from smelters or refiners that are in compliance with the RMAP assessment protocols.

The Company is a downstream consumer of conflict minerals and is many steps removed from the mining of conflict minerals. The Company does not purchase raw ore or unrefined conflict minerals, and, to the best of its knowledge, conducts no purchasing activities directly in the Covered Countries.

5.Report Annually on Supply Chain Due Diligence

This Report (and the related Form SD) was filed with the SEC and is available on the Company’s website at: http://www.johnsoncontrols.com/corporate-sustainability/reporting-and-policies.

B. Due Diligence Results

The RCOI, including the use of the Surveys, and the Company’s due diligence efforts described above were designed to provide the Company with information on the smelters and refiners that the In-Scope Suppliers, and their suppliers, used to process conflict minerals in the products supplied to the Company. The Company must rely on responses from the suppliers in order to determine the facilities used to process conflict minerals. Similar to the Company, suppliers generally do not have a direct relationship with the facilities used to process conflict minerals; therefore, some suppliers responded that they were unable to provide smelter and refinery information at this time. Accordingly, the Company does not know as of this reporting period all the facilities used to process, or the country of origin of, all the conflict minerals included in its products.

Based on a review of the received and accepted responses, 19% of the suppliers acknowledged that they sourced 3TG from the Covered Countries. Approximately 36% of those suppliers indicated that they only sourced from smelters and refiners that the RMI identifies as conformant with RMAP standards. For the remaining 64%, the suppliers were not able to confirm if the 3TG had been sourced from smelters/mines financing or benefiting armed groups. None of the responses acknowledged that 3TG was sourced from smelters/mines that financed or benefited armed groups in the Covered Countries.

Approximately 12% (544 suppliers) of In-Scope Suppliers indicated possible sourcing from non-conformant or high-risk smelters or refiners. One supplier indicated that it sourced 3TG from a non-conformant smelter that was used in products sold to the Company. The Company engaged in follow up with the supplier following receipt of this information and, during the reporting year, the supplier was able to subsequently update its original response to certify that the smelter had obtained compliance with RMAP standards, thereby achieving conformant smelter status. No other follow-up responses or subsequent engagement with suppliers confirmed whether the minerals sourced from these smelters were present in the supplied products to the Company.

C. Risk Mitigation Measures

In order to mitigate risk related to conflict minerals in Johnson Controls’ supply chain, the Company’s current processes and procedures include:

•Aggregation of In-Scope Supplier responses to the RMI smelter and refiner database, confirm the accuracy and completeness of supplier responses and disclosed smelters and refiners against available data, and act upon discrepancy findings.

•The Company’s global terms and conditions of purchase to require suppliers to disclose to the Company, in writing, the content and the origin of the conflict minerals in the materials and/or products they provide to the Company.

In order to further mitigate the risk that conflict minerals in the Company's supply chain benefited armed groups in the Covered Countries and to identify the origin of those conflict minerals, the Company will continue to initiate efforts to strengthen the response rate and the completeness of the Surveys:

•By continuing to incentivize suppliers tracked with the Company's performance scorecards to disclose to the Company the origin of the conflict minerals in the materials and/or products they provide to the Company;

•By directing suppliers to the Company's corporate policy with respect to the sourcing of conflict minerals;

•By providing training and educational materials to suppliers and smelters, including suppliers not deemed to be In-Scope Suppliers;

•By following up with all suppliers who indicated that they might be sourcing conflict minerals from the non-conformant or high-risk smelters in Covered Countries;

•By requesting that suppliers remove non-conformant smelters and refiners from their supply chain and obtain minerals from smelters and refiners that are compliant according to the RMAP;

•By directly communicating with non-conformant or potentially non-conformant smelters and refiners in order to undergo a third party audit through the RMAP to change their current smelter status; and

•By re-evaluating business partnerships with suppliers who failed to reply, failed to meet the expected due diligence criteria or failed to deliver remedy plan for removing non-conformant smelters' or refiners' minerals from products delivered to the Company.

VII. Determination

At this time, for calendar year 2023, the Company is unable to determine the mine or country of origin of all of its necessary conflict minerals or the facilities used to process conflict minerals in its supply chain or if the conflict minerals sourced from non-conformant smelters or refiners were present in the supplied products to the Company due to either a lack of Survey responses, inconclusive Survey responses, or lack of follow-up responses to communications addressing non-conformant smelters or refiners from its In-Scope Suppliers. As such, the Company is currently unable to determine whether or not its products manufactured in the 2023 calendar year have been found to be free of necessary conflict minerals that directly or indirectly financed or benefited armed groups in the Covered Countries.

This Report includes forward-looking statements, within the meaning of the Private Securities Litigation Reform Act of 1995, that involve risks and uncertainties. Forward-looking statements provide current expectations of future events based on certain assumptions and include any statement that does not directly relate to any historical or current fact. Forward-looking statements can also be identified by words such as “expects,” “plans,” “intends,” “will,” “may,” and similar terms. Forward-looking statements are not guarantees of future performance. The Company assumes no obligation to revise or update any forward-looking statements for any reason, except as required by law. Subsequent events may affect the Company's future determinations under the Rule.

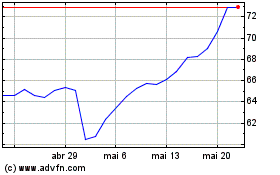

Johnson Controls (NYSE:JCI)

Gráfico Histórico do Ativo

De Mai 2024 até Jun 2024

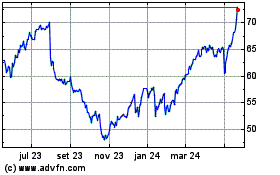

Johnson Controls (NYSE:JCI)

Gráfico Histórico do Ativo

De Jun 2023 até Jun 2024