UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM SD

Specialized Disclosure Report

TOWER SEMICONDUCTOR LTD.

(Exact name of registrant as specified in its charter)

|

ISRAEL

|

000-24790

|

N/A

|

|

(State or other jurisdiction

|

(Commission

|

(IRS Employer

|

|

of incorporation or organization)

|

File Number)

|

Identification No.)

|

| |

|

|

Ramat Gavriel Industrial Park, P.O. Box 619,

|

|

|

Migdal Haemek, Israel

|

|

|

(Address of principal executive offices)

|

(Zip Code)

|

Nati Somekh

Telephone:

+972-4-650-6109

(Name and telephone number, including area code, of the person to contact in connection with this report.)

Check the appropriate box to indicate the rule pursuant to which this Form is being filed, and provide the period to which the information in this Form applies:

☒ Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023.

☐ Rule 13q-1 under the Securities Exchange Act (17 CFR 240.13q-1) for the fiscal year ended.

Introduction

This Specialized Disclosure Report on Form SD (“Form SD”) of Tower Semiconductor Ltd. for the year ended December 31, 2023 is presented to comply with Rule 13p-1 under the Securities Exchange Act of

1934 (the “Rule”). Unless the context indicates otherwise, “Tower,” “we,” “us” and “our” refers to Tower Semiconductor Ltd. and its consolidated subsidiaries as of December 31, 2023. The Rule was adopted by the Securities and Exchange Commission (the

“SEC”) to implement reporting and disclosure requirements related to “conflict minerals” as directed by the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010. Conflict minerals are defined by the SEC as gold as well as

columbite-tantalite (coltan), cassiterite, wolframite, or their derivatives, which are limited to tantalum, tin, and tungsten. The Rule imposes certain reporting obligations on SEC registrants for whom conflict minerals are necessary for the

functionality or production of products manufactured by the registrant or contracted by the registrant to be manufactured (such minerals are referred to as “necessary conflict minerals”). With respect to its necessary conflict minerals, the

registrant must conduct in good faith a reasonable country of origin inquiry ("RCOI") designed to determine whether any of its necessary conflict minerals originated in the Democratic Republic of the Congo (“DRC”) or an adjoining country,

collectively defined as the “Covered Countries”. If, based on such RCOI, the registrant knows or has reason to believe that any of its necessary conflict minerals originated or may have originated in a Covered Country and knows or has reason to

believe that those necessary conflict minerals may not be solely from recycled or scrap sources, the registrant must conduct due diligence on the source and chain of custody of its necessary conflict minerals in order to determine whether such

necessary conflict minerals did or did not directly or indirectly finance or benefit armed groups in the Covered Countries. Products which do not contain, or are manufactured without the use of, necessary conflict minerals that directly or indirectly

finance or benefit armed groups in the Covered Countries are considered “DRC conflict free”.

We use the term “conflict free” in this Form SD in a broader sense to refer to suppliers, supply chains, smelters and refiners whose sources of conflict minerals did not or do not directly or

indirectly finance or benefit armed groups in the Covered Countries.

The content of any website referred to in this Form SD is included for general information only and is not incorporated by reference into this document.

Company Overview

We are the leading foundry of high-value analog semiconductor solutions, provides technology, development, and process platforms for our customers in growing markets such as consumer, industrial,

automotive, mobile, infrastructure, medical and aerospace and defense. Our processes use chemical materials, chemical processes and other materials and equipment on silicon wafers, based on the product design by our customers. As a pure-play

foundry, we do not offer products of our own. We currently offer the process technology geometries of 0.35, 0.50, 0.55, 0.60, 0.80-micron and above on 150-mm wafers and 0.35, 0.18, 0.16 and 0.13 -micron on 200-mm wafers and 65 nanometer on 300-mm

wafers. We also provide design support and complementary technical services. Our customers and/or our customers’ customers use the wafers for their end products, which are sold and/or used in diverse markets, including consumer applications, personal

computers, communications, handsets and smartphones, automotive, industrial, aerospace and medical devices.

We currently operate six facilities ("fabs") in several geographic regions: two fabs (for 150mm and 200mm wafers) located in Migdal Haemek, Israel, one fab (for 200mm wafers) located in Newport

Beach, California, one fab (for 200mm wafers) located in San Antonio, Texas, and two additional fabs (for 200mm and 300mm wafers) located in the Hokuriku region of Japan. We are focused on establishing leading market share in high-growth specialized

markets by providing our customers with high-value, high quality, wafer foundry services. We use standard analog complementary metal oxide semiconductor (“CMOS”) process technology, as well as specialized specific technologies including CMOS image

sensors, non-imaging sensors, including sensors on Gallium Nitride, micro-electromechanical systems (MEMS), wireless antenna switch Silicon-on-Insulator (SOI), mixed-signal, radio frequency CMOS (RFCMOS), bipolar CMOS (BiCMOS), and silicon-germanium

BiCMOS (SiGe BiCMOS or SiGe), silicon photonics, high voltage CMOS, radio frequency identification (RFID) technologies and power management.

Overview of Tower’s Efforts to Identify Conflict Minerals in its Processes

To comply with the Rule, we reviewed the wafers we processed in 2023 to determine whether conflict minerals were necessary for their functionality or production. Based on this review, we determined

that tungsten and/or tantalum were used in the processing of most of the wafers we process and are contained in certain of the wafer we process.

Supply Chain Description

All of our wafers are processed in our own fabs. Tower does not purchase any tungsten or tantalum directly from smelters, refiners or mines, and is many steps away in the supply chain from the mining

of the necessary conflict minerals in the wafers we process. Rather, the necessary conflict minerals are obtained from our direct suppliers, who obtain them from a variety of sources worldwide. As a result, we rely on our direct suppliers to assist

with our RCOI and due diligence efforts, including the identification of smelters and refiners as the source of any necessary conflict minerals contained in the materials which our direct suppliers supply to us.

SECTION 1 – CONFLICT MINERALS DISCLOSURE

Item 1.01. Conflict Minerals Disclosure and Report.

Description of Reasonable Country of Origin Inquiry

As indicated, Tower concluded that during 2023, it had processed wafers in which tungsten and/or tantalum were necessary for their functionality or production. As a result, we conducted in good faith

an RCOI that was designed to reasonably determine whether any of our necessary conflict minerals originated in the Covered Countries or were from recycled or scrap sources.

As part of the RCOI, we conducted a supply chain survey of our direct suppliers of tungsten and tantalum (and of any material used in our processes that contains tungsten or tantalum) to obtain

country of origin information using the Conflict Minerals Reporting Template (the "Template” or “CMRT), which is a standardized survey tool published by the Responsible Minerals Initiative (“RMI”). RMI operates the Responsible Mineral Assurance

Process (“RMAP”), a program that identifies smelters and refiners that produce responsibly sourced materials by using third-party auditors to independently verify that these smelters and refiners have systems in place to responsibly source minerals

in conformance with RMAP standards. The Template, which requests that our direct suppliers identify the smelters, refiners and countries of origin of the necessary conflict minerals they supply to Tower, was developed to facilitate disclosure and

communication of information regarding smelters and refiners that provide material in a company’s supply chain. The Template includes, among others, questions regarding a company’s conflict-free policy, engagement with its direct suppliers, and a

listing of the smelters the company and its suppliers use. In addition, the Template contains questions about the origin of conflict minerals included in their products, as well as supplier due diligence. Written instructions regarding use of the

questionnaire and other information about RMI and RMAP is available on RMI’s website at https://www.responsiblemineralsinitiative.org/.

We received responses from all of our direct suppliers of tungsten and tantalum (and from all of our direct suppliers of any material used in our processes that contain tungsten or tantalum). We then confirmed whether or

not each smelter or refiner they identified as providing conflict minerals was found to be conformant with RMAP standards.

Conclusion Based on Reasonable Country of Origin Inquiry

As a result of our survey regarding 2023 activity, five out of our seven direct suppliers of tungsten or any material used in our processes that contain tungsten indicated that their supply chain includes smelters or

refiners sourcing tungsten from the Covered Countries. In addition, each of the seven suppliers confirmed that all of the smelters or refiners they identified as suppliers of tungsten had been designated as RMAP conformant.

Regarding tantalum, each of two direct suppliers of tantalum or any material used in our processes that contain tantalum indicated that their supply chain includes smelters or refiners sourcing

tantalum from the Covered Countries. In addition, both suppliers confirmed that all of the smelters and refiners they identified as suppliers of tantalum had been designated as RMAP conformant.

Because we know or have reason to believe that a certain amount of the tungsten and tantalum used in the processing of certain of the wafers we process and/or contained in certain of the wafers we

process originated or may have originated in a Covered Country, we conducted due diligence on the source and chain of custody of the tungsten and tantalum used in the processing of, and/or contained in, the wafers we process. Our due diligence was

designed to conform to the Organization for Economic Cooperation and Development’s “Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas", Third Edition (April 2016).

The due diligence measures that we performed are discussed further in the conflict minerals report filed as Exhibit 1.01 hereto.

Conflict Minerals Disclosure

This Form SD and the conflict minerals report, filed as Exhibit 1.01 hereto, are publicly available on our website at https://ir.towersemi.com/financial-information/sec-filings.

Item 1.02. Exhibit.

The Conflict Minerals Report required by Item 1.01 of Form SD is filed as Exhibit 1.01 to this Form SD.

SECTION 2 – RESOURCE EXTRACTION ISSUER DISCLOSURE

Item 2.01. Resource Extraction Issuer Disclosure and Report.

Not applicable.

SECTION 3 – EXHIBITS

Item 3.01. Exhibits.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

Tower Semiconductor Ltd.

(Registrant)

|

By: /s/ Nati Somekh

|

May 30, 2024

|

|

Nati Somekh

Senior Vice President, Chief Legal Officer and Corporate Secretary

|

5

Exhibit 1.01

Tower Semiconductor Ltd.

Conflict Minerals Report

For the Year Ended December 31, 2023

This conflict minerals report for the year ended December 31, 2023 is presented to comply with Section 13(p) of the Securities Exchange

Act of 1934 and Rule 13p-1 (the "Rule") and Form SD adopted thereunder. The Rule was adopted by the Securities and Exchange Commission (the "SEC") to implement reporting and disclosure requirements related to conflict minerals as directed by the

Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010. The Rule imposes certain reporting obligations on SEC registrants for whom conflict minerals are necessary for the functionality or production of products by the registrant or

contracted by the registrant to be processed (such minerals are referred to as “necessary conflict minerals”). "Conflict minerals" are defined as gold as well as columbite-tantalite (coltan), cassiterite, wolframite, or their derivatives, which are

limited to tin, tantalum and tungsten (collectively referred to as “3TG Minerals”).

With respect to its necessary conflict minerals, the registrant must conduct in good faith a reasonable country of origin inquiry

designed to determine whether any of its necessary conflict minerals originated in the Democratic Republic of the Congo (“DRC”) or an adjoining country, collectively defined as the “Covered Countries”. If, based on such inquiry, the registrant knows

or has reason to believe that any of its necessary conflict minerals originated or may have originated in a Covered Country and knows or has reason to believe that those necessary conflict minerals may not be solely from recycled or scrap sources,

the registrant must conduct due diligence on the source and chain of custody of its necessary conflict minerals in order to determine whether such necessary conflict minerals directly or indirectly finance or benefit armed groups in the Covered

Countries, and it must submit a conflict minerals report as an exhibit to its Form SD that includes a description of those due diligence measures. In accordance with the instructions and related guidance to Form SD, this conflict minerals report has

not been audited by an independent private sector auditor.

The content of any website referred to in this conflict minerals report is included for general information only and is not incorporated

by reference into this document.

Design and Description of Conflict Minerals Diligence Program

The due diligence efforts by Tower Semiconductor Ltd. (unless the context indicates otherwise, “Tower,” “Company,” “we,” “us” and “our”

refers to Tower Semiconductor Ltd. and its consolidated subsidiaries for 2023) have been designed to conform with the framework provided by the Organization for Economic Cooperation and Development’s ("OECD’s") “Due Diligence Guidance for Responsible

Supply Chains of Minerals from Conflict-Affected And High-Risk Areas” (Third Edition, April 2016) (the “OECD Guidance”).

Consistent with the OECD Guidance, our due diligence in respect of 2023 consisted of a five-step process described below:

|

(i) |

Establish Strong Company Management Systems

|

Tower is dedicated to corporate social responsibility and has adopted several management systems to address the issue of conflict minerals

used in the processing of, and/or contained in, the wafers it processes, including:

|

(i) |

a Company code of ethics requiring all employees, officers and directors to comply with all applicable laws, rules and regulations of the U.S., Israel and other

countries (available at: https://towersemi.com/about/corporate-social-responsibility-esg/social/;

|

|

(ii) |

compliance since 2014 with the Responsible Business Alliance (RBA), which is a nonprofit comprised of electronics, retail, auto and toy companies committed to

supporting the rights and well-being of workers and communities worldwide affected by global supply chains. RBA members commit and are held accountable to a common Code of Conduct and utilize a range of RBA training and assessment tools to

support continuous improvement in the social, environmental and ethical responsibility of their supply chains,

|

|

(iii) |

a code of ethics for suppliers requiring suppliers to conduct their business in an ethical

manner and act with integrity, including by ensuring that products supplied to Tower do not contain metals derived from minerals or their derivatives originating from conflict regions that directly or indirectly finance or benefit armed

groups,

|

|

(iv) |

a conflict minerals policy as described below, and

|

|

(v) |

a team of Company employees, consisting of senior operations, engineering, QA, regulatory compliance and legal personnel, that oversees implementation of the Company's

conflict minerals compliance strategy (the “Conflict Minerals Oversight Team”). In addition, senior management of the Company is periodically briefed by the Company’s Corporate Compliance Officer about conflict minerals compliance efforts.

|

The code of ethics for suppliers and the conflict minerals policy are each available at: https://towersemi.com/about/corporate-social-responsibility-esg/social-supply-chain/. Suppliers are required as part of the terms and conditions of their supply with the Company to

comply with each such policy.

The Company’s conflict minerals policy states, in part, that the Company:

|

• |

Avoids the use of conflict minerals that directly or indirectly finance or benefit armed groups in the Covered Countries;

|

|

• |

Expects its suppliers to have in place policies and due diligence procedures that will

ensure that products and components that they supply containing conflict minerals, including conflict minerals from Covered Countries, are in fact "conflict-free", meaning that they do not directly or indirectly finance or benefit

armed groups in Covered Countries;

|

|

• |

Requires the Company's direct suppliers to provide it with annual declarations regarding

their use of conflict minerals (utilizing a format described below);

|

|

• |

Reserves the right to take appropriate action to enforce its conflict minerals policy, including discontinuing purchases from suppliers that fail to comply; and

|

|

• |

Is committed to responsible sourcing of conflict minerals throughout its supply chain and to continued compliance with applicable SEC rules and regulations in this

area.

|

The conflict minerals policy also directs any questions about such policy to the Company's Corporate Compliance Officer at

compliance.officer@towersemi.com.

In addition to the measures described above and in order to provide transparency within our supply chain, we have adopted the Conflict

Minerals Reporting Template (the "Template” or “CMRT”) to directly survey our suppliers. The CMRT is a standardized survey tool published by the Responsible Minerals Initiative (“RMI”). RMI operates the Responsible Mineral Assurance Process (“RMAP”),

a program that identifies smelters and refiners that produce responsibly sourced materials by using third-party auditors to independently verify that these smelters and refiners have systems in place to responsibly source minerals in conformance with

RMAP standards.

We also include provisions in our terms and conditions attached to each purchase order we issue that require our suppliers of 3TG

Minerals to (i) submit a completed CMRT in January of each year, which covers the previous calendar year, and (ii) supply only conflict-free materials to Tower. Suppliers are encouraged to use only refiners and smelters who are RMAP conformant, and,

after receiving completed CMRTs from suppliers, we confirm that such refiners and smelters are in fact designated as RMAP conformant.

All responses from suppliers are recorded and stored in an electronic database and are maintained for a minimum of five years.

|

(ii) |

Identify and Assess Risk in the Supply Chain

|

We have identified two primary risks regarding our

suppliers, as follows: (i) not receiving timely or accurate information, and (ii) difficulty in replacing a supplier should we determine that such supplier obtained or appears to have obtained conflict minerals from sources that support armed

conflict in the Covered Countries.

Because we do not purchase tungsten and tantalum directly

from smelters, refiners or mines and are many steps removed in the supply chain from mining of such tungsten and tantalum, we focus our efforts on surveying our direct suppliers who were required to survey their own suppliers (i.e., our upstream

suppliers) in order to receive the required information. As indicated above, we use the Template to conduct such a survey of each of our direct suppliers in order to identify and receive information regarding smelters and refiners of tungsten and

tantalum in our supply chain.

Following an annual distribution of the Template to our direct suppliers of tungsten and/or tantalum or any material used in our

processes that contains tungsten and/or tantalum, we follow-up to receive responses with completed CMRT from all of our suppliers. Templates submitted by such direct suppliers are reviewed for reasonableness and for missing or incomplete data, and we

contact such direct suppliers as necessary to obtain clarifications or additional information where needed. Thereafter, to ensure compliance, we compare the smelters or refiners identified by those suppliers in their submitted Templates with the list

of facilities designated by RMI as RMAP conformant.

As disclosed on our website, our ethics helpline is

available to employees and others to report any violations of the law or violations of our codes of ethics.

|

(iii) |

Design and Implement a Strategy to Respond to Identified Risks

|

Per the Company’s conflict minerals policy, we expect

suppliers to have in place due diligence policies and procedures that ensure that materials that it supplies to Tower containing 3TG Minerals are in fact "conflict-free", meaning that they do not directly or indirectly finance or benefit armed

groups in the Covered Countries. If at any time the Company is not satisfied with a supplier's Template responses or believes that adequate policies and procedures are not in place, it reserves the right to take appropriate action to enforce its

conflict minerals policy, including discontinuing purchases from such suppliers.

In addition, the Conflict Minerals Oversight Team

and Tower’s Corporate Compliance Officer are responsible for collecting and reviewing all relevant conflict minerals data and formulating a proposed corporate strategy to address any risks identified by such review. Senior management of the Company is periodically briefed by the Company’s Corporate Compliance Officer about conflict minerals compliance efforts.

By taking these steps, we manage the risks associated with our supply chain by:

|

- |

engaging with suppliers to obtain current, accurate and complete information about their supply chains; and

|

|

- |

encouraging suppliers to implement responsible sourcing policies and working with smelters and refiners that have obtained a “conflict-free” designation from a

third-party auditor such as under RMAP.

|

Finally, we have established an escalation process to

contact suppliers upon obtaining any information that indicates that such suppliers may be sourcing necessary conflict minerals from any of the Covered Countries without a "conflict free" designation. Steps considered by the Company in such

instances may include requiring a contracted supplier to find an alternative source for the necessary 3TG Minerals for use in products or components supplied to the Company, obtaining confirmation that the material provided to us is “conflict

free”, or, if appropriate, in light of all relevant circumstances, seeking an alternate source of supply and suspending or terminating the Company’s contractual relationship with such supplier.

|

(iv) |

Carry Out Independent Third-Party Audit of Smelter/Refiner's Due Diligence Practices

|

The Template provided to our suppliers requests information on the smelters and refiners used to provide the tungsten and tantalum in

the wafers we process. We do not typically have a direct relationship with smelters and refiners of such minerals and are unable to perform or direct audits of these entities within our supply chain. Instead, in order to ensure compliance, we compare information regarding refiners and smelters provided by our suppliers in their Template with lists of refiners and smelters designated by RMI as RMAP

conformant.

|

(v) |

Report Annually on Supply Chain Due Diligence

|

This conflict minerals report is available on our website at https://ir.towersemi.com/financial-information/sec-filings and has also been filed with the SEC.

Results of our Due Diligence Measures

Inherent Limitations on Due Diligence Measures

We believe that following the OECD Guidance and usage of

the Template represents reasonable and reliable ways to gather information on the source of conflict minerals in the products we process.

Our due diligence measures can provide only reasonable, not absolute, assurance regarding the source and chain of custody of the

necessary conflict minerals in the products we process. Our due diligence processes are based on the data received from our direct suppliers of tungsten and/or tantalum or any material used in our processes that contains tungsten and/or tantalum,

which in turn is based on information received by those suppliers seeking similar data within their supply chains to identify the original sources of the necessary conflict minerals. We also rely, to a large extent, on information collected through

the RMAP and designations made by RMI as part of RMAP, which may not yield accurate and complete information or make accurate designations in all cases.

Supplier Chain Survey Responses

As a result of our survey regarding 2023 activity, each of two direct suppliers of tantalum and/or any material used in our processes

that contains tantalum indicated that their supply chain includes smelters or refiners sourcing from the Covered Countries, as did five of our seven direct suppliers of tungsten and/or any material used in our processes that contains tungsten.

However, each of the smelters and refiners identified by such suppliers as sourcing tantalum or tungsten from Covered Countries has been designated as RMAP conformant.

The table below lists the facilities identified by our direct suppliers which, to the extent known, may have processed the tantalum

and/or tungsten used in the wafers we process or in our processes in 2023. All of the below listed facilities have been designated as RMAP conformant.

Tantalum:

|

F&X Electro-Materials Ltd.

|

Germany

|

|

XIMEI RESOURCES (GUANGDONG) LIMITED

|

India

|

|

JiuJiang JinXin Nonferrous Metals Co., Ltd.

|

CHINA

|

|

Jiujiang Tanbre Co., Ltd.

|

CHINA

|

|

Metallurgical Products India Pvt., Ltd.

|

INDIA

|

|

Mitsui Mining & Smelting

|

JAPAN

|

|

NPM Silmet AS

|

Indonesia

|

|

Ningxia Orient Tantalum Industry Co., Ltd.

|

Germany

|

|

Yanling Jincheng Tantalum & Niobium Co., Ltd.

|

CHINA

|

|

Telex Metals

|

Japan

|

|

Ulba Metallurgical Plant JSC

|

KAZAKHSTAN

|

|

Hengyang King Xing Lifeng New Materials Co., Ltd.

|

Indonesia

|

|

D Block Metals, LLC

|

UNITED STATES OF AMERICA

|

|

FIR Metals & Resource Ltd.

|

Indonesia

|

|

Jiujiang Zhongao Tantalum & Niobium Co., Ltd.

|

CHINA

|

|

XinXing HaoRong Electronic Material Co., Ltd.

|

Indonesia

|

|

KEMET de Mexico

|

Japan

|

|

TANIOBIS Co., Ltd.

|

THAILAND

|

|

TANIOBIS GmbH

|

GERMANY

|

|

Materion Newton Inc.

|

Japan

|

|

TANIOBIS Japan Co., Ltd.

|

JAPAN

|

|

TANIOBIS Smelting GmbH & Co. KG

|

GERMANY

|

|

Global Advanced Metals Boyertown

|

UNITED STATES OF AMERICA

|

|

Global Advanced Metals Aizu

|

JAPAN

|

|

Jiangxi Tuohong New Raw Material

|

Indonesia

|

Tungsten:

|

A.L.M.T. Corp.

|

United States Of America

|

|

Kennametal Huntsville

|

UNITED STATES OF AMERICA

|

|

Chongyi Zhangyuan Tungsten Co., Ltd.

|

CHINA

|

|

Global Tungsten & Powders Corp.

|

UNITED STATES OF AMERICA

|

|

Hunan Chenzhou Mining Co., Ltd.

|

Turkey

|

|

Japan New Metals Co., Ltd.

|

United States Of America

|

|

Wolfram Bergbau und Hutten AG

|

AUSTRIA

|

|

Xiamen Tungsten Co., Ltd.

|

CHINA

|

|

Ganzhou Jiangwu Ferrotungsten Co., Ltd.

|

United States Of America

|

|

Jiangxi Yaosheng Tungsten Co., Ltd.

|

United States Of America

|

|

Xiamen Tungsten (H.C.) Co., Ltd.

|

CHINA

|

|

Jiangxi Gan Bei Tungsten Co., Ltd.

|

CHINA

|

|

Ganzhou Seadragon W & Mo Co., Ltd.

|

CHINA

|

|

Chenzhou Diamond Tungsten Products Co., Ltd.

|

CHINA

|

|

H.C. Starck Tungsten GmbH

|

United States Of America

|

|

TANIOBIS Smelting GmbH & Co. KG

|

United States Of America

|

|

Masan High-Tech Materials

|

VIET NAM

|

|

Jiangwu H.C. Starck Tungsten Products Co., Ltd.

|

CHINA

|

|

Niagara Refining LLC

|

UNITED STATES OF AMERICA

|

|

China Molybdenum Tungsten Co., Ltd.

|

United States Of America

|

In addition, our suppliers provided us with information regarding the countries of origin of the tantalum and tungsten supplied by

certain of the above smelters and refiners, a list of which is provided below. Our suppliers did not provide specific country of origin information for certain smelters and refiners. Due to the incompleteness of this information, Tower is unable at

this time to determine and describe in this report a complete list of specific countries of origin of such conflict minerals. Tower shall make commercially reasonable efforts to obtain the required information in order to make such determination.

|

• |

Democratic Republic of Congo (DRC)

|

|

• |

United States of America (USA)

|

Future Due Diligence Measures

For the calendar year ending December 31, 2023, we have engaged in the due diligence process described above. We will also continue to

attempt to validate supplier responses using information collected through independent conflict-free smelter validation programs, such as that of RMAP, and will take measures as needed to address any potential risks that are identified through these

due diligence efforts.

This Form SD and conflict minerals report includes certain

“forward-looking” statements within the meaning of Section 21E of the Securities Exchange Act of 1934. The use of the words “projects,” “expects,” “may,” “plans” or “intends,” or words of similar import, identifies a statement as “forward-looking”.

There can be no assurance, however, that actual results will not differ materially from our expectations or projections. Factors that could cause actual results to differ from our expectations or projections include the risks and uncertainties relating to our business described in in “Item 3. Key Information-D. Risk

Factors” of our Annual Report on Form 20-F.

8

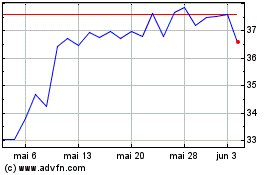

Tower Semiconductor (NASDAQ:TSEM)

Gráfico Histórico do Ativo

De Out 2024 até Nov 2024

Tower Semiconductor (NASDAQ:TSEM)

Gráfico Histórico do Ativo

De Nov 2023 até Nov 2024